ABOUT KEMING

Keming Machinery is located in the famous industrial town Yinzhou, Ningbo in China. It is very convenient to be reached with an advantageous geographic position. Our company was established in 2003, it covers a total area of 5000 square meters and now has more than 50 employees.We have the modern factory and the advanced CNC machining equipment. Now focus on the steel investment casting oem production. Keming Machinery provides casting services such as Investment Casting, Shell Mold Sand Casting, Lost Foam Casting, Water Glass Casting, Lost Wax Casting, etc.

What can KEMING do for you

KEMING is committed to providing the highest quality precision metal parts manufacturing services

- Investment Casting: Produces high-precision, complex metal parts using wax patterns and ceramic molds.

- Shell Mold Sand Casting: Uses a ceramic shell around a sand mold for durable, detailed metal castings.

- Lost Foam Casting: Creates castings by replacing foam patterns with molten metal in a single-step process.

- Lost Wax Casting: Produces intricate metal parts by casting molten metal into wax-derived ceramic molds.

- Precision Machining: Provides accurate machining to achieve tight tolerances and fine surface finishes.

- CNC Milling Machining: Uses computer-controlled tools for precise and repeatable metal part manufacturing.

- Turning Machining: Rotates workpieces against cutting tools to shape cylindrical metal parts.

- Machining Workshop: Equipped facility for various metal cutting, shaping, and finishing operations.

Our Factory and Equipments

Advanced Machining Equipments

The KEMING factory has advanced machining equipment that can meet the production needs of various high-precision parts. The factory is equipped with 30 lathes and 10 CNC machines, which ensure high efficiency and high precision of machining. Through advanced CNC technology, KEMING is able to achieve precision manufacturing of complex parts and ensure stable and reliable product quality.

Casting Production Lines

Our factory has two casting process production lines, focusing on the production of high-quality castings. With the modern machining workshop, the entire production process is scientific and reasonable, which greatly improves production efficiency and product consistency. The workshop environment is clean and the process flow is standardized to ensure that every part meets strict quality standards.

Sufficient Production Capacity

KEMING's annual output exceeds 2,000 tons of precision casting parts, with sufficient production capacity to meet the needs of large-volume orders. The company has a rich variety of products developed and produced, and has developed more than 5,000 different types of products, which are widely used in multiple industries. The diverse product lines demonstrate KEMING's strong R&D capabilities and market adaptability.

Our Castings Quality Control

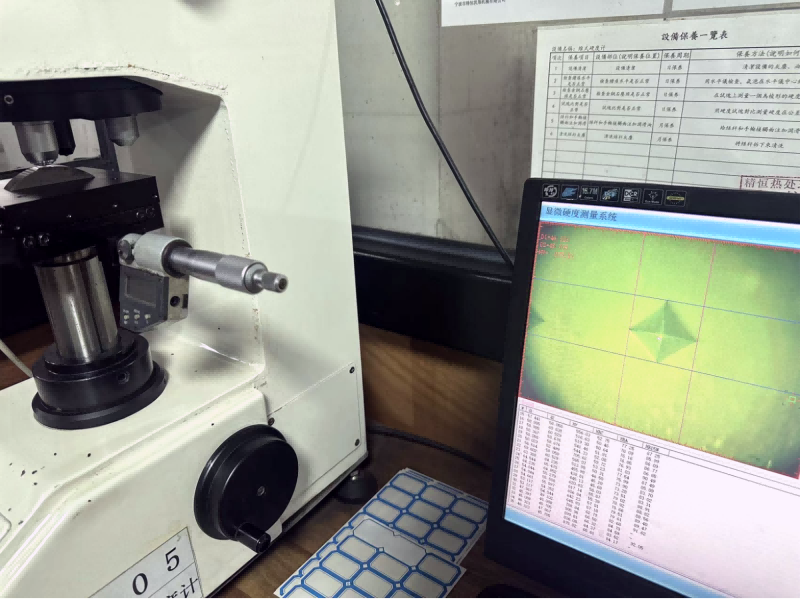

Hardness Test

For Brinell testing, we use a spherical penetrating body to press into the surface of the castings. For Rockwell, a bullet- or cone-shaped penetrating body is used, and for Vickers, we use a diamond pyramidal body.

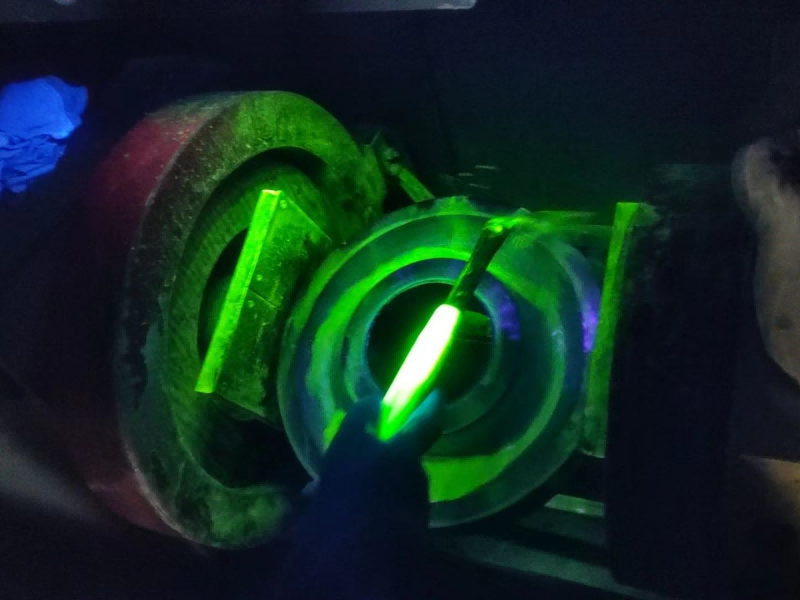

Magnetic Particle Inspection

Our wet MPI method provides enhanced sensitivity, detecting discontinuities with a maximum depth of 1/4 inch. We carry out MPI testing on heat-treated or machined castings to ensure that there are no defects.

Material Test

To ensure the veracity of the material certification provided by the factory, we conduct a chemical analysis of a small piece before each batch of metal ingot is used. We also inspect the molten metal before pouring and conduct testing on the completed samples.

X-RAY TEST

At keming machinery, we use X-Ray testing to detect various defects including gas porosity, gas holes, micro-porosity/shrinkage porosity, shrinkage, cracks, dross, cold shuts, segregation, misruns, and diffraction mottling.

Our International Certificates

KEMING is well-versed in a wide range of industrial standards. Our products and services meet strict quality requirements. We comply with many important standards from around the world. These include the Chinese GB standard, which ensures safety and quality in China. We also follow the American ASTM and AISI standards, known for their rigorous testing and material specifications. In Europe, we adhere to the German DIN, French NF, and British BS standards. Additionally, we meet the Japanese JIS standard, which is known for precision and reliability. Our certifications also cover the Australian AS standard and the Association of American Railroads (AAR) requirements. By following these diverse standards, KEMING guarantees that our products are reliable, safe, and suitable for international markets. This wide certification range reflects our commitment to quality and global cooperation.