YOUR ONE-STOP CASTINGS SOLUTION MANUFACTURER

We focus on providing high-quality products to our customers. KEMING is an ISO9001 certified company, which shows our commitment to quality management. We work closely with OEM and ODM companies that require very high standards. Our team uses advanced technology and strict quality control to ensure every product meets customer expectations.

At KEMING, customer satisfaction is our top priority. We are dedicated to delivering reliable and efficient casting solutions. Whether you need small or large orders, we can handle them with care and professionalism. Choose KEMING for your casting manufacturing needs and experience excellent service and quality.

Investment Casting

KEMING specializes in custom metal investment casting parts, offering hole diameters as small as 0.5mm and minimum casting wall thickness of 3mm from design to production.

Lost Wax Casting

The size tolerance achievable in lost wax casting by KEMING typically ranges from ±0.1 mm to ±0.5 mm (±0.004 inches to ±0.020 inches) for linear dimensions.

Shell Mold Sand Casting

KEMING’s shell mold sand casting offers high accuracy, smooth finishes, and complex shapes, ideal for small to medium metal parts across industries.

Lost Foam Casting

Lost foam casting enables complex, detailed shapes with less machining and cost savings. KEMING ensures quality through precise pattern making, coating, and metal pouring.

Precision Machining

KEMING offers cold processing and precision machining of steel, iron, aluminum, copper, and more, backed by 20+ years of experience delivering high-quality components.

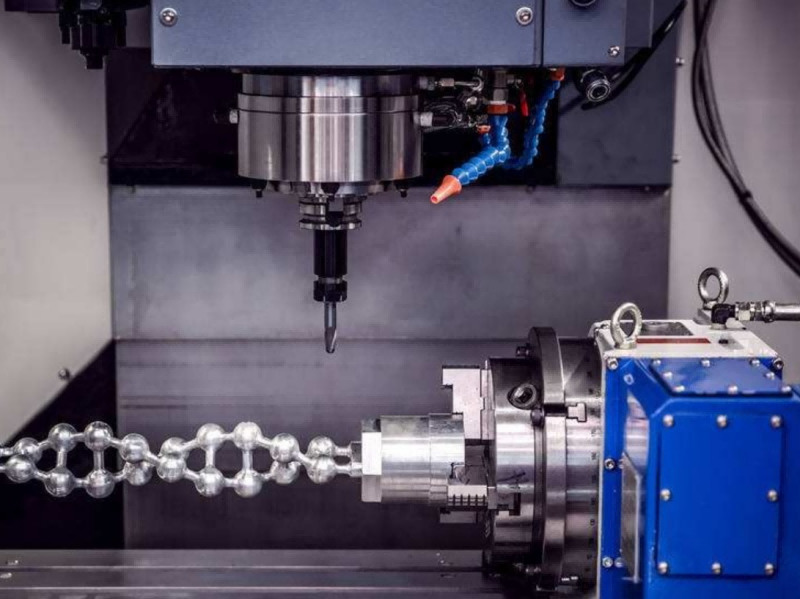

CNC Milling Machining

With the latest manufacturing technology & advanced CNC machines (3-, 4- and 5-axis machine centers), KEMING can customize all shapes of metal parts to your drawings specification.

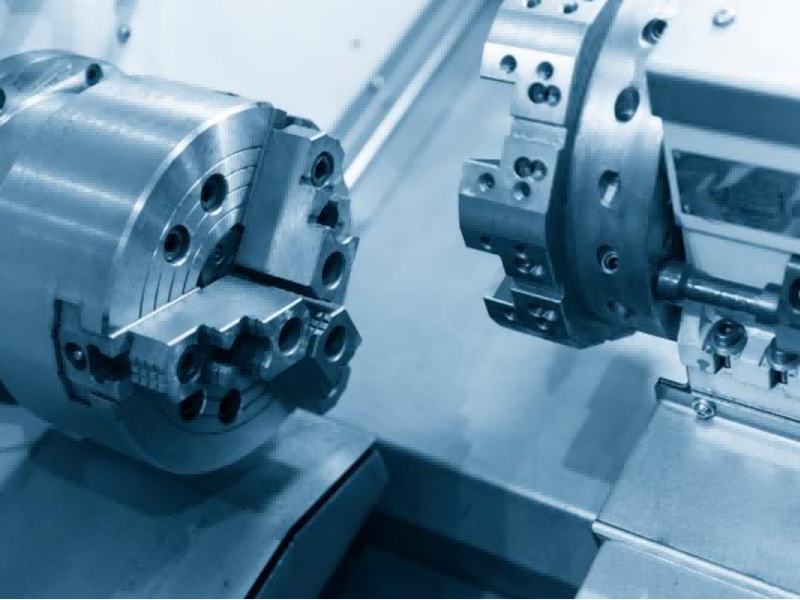

CNC Turning Machining

KEMING CNC turning is widely utilized in manufacturing for its ability to produce custom parts with tight tolerances and repeatability, making it suitable for a variety of materials and production volumes.

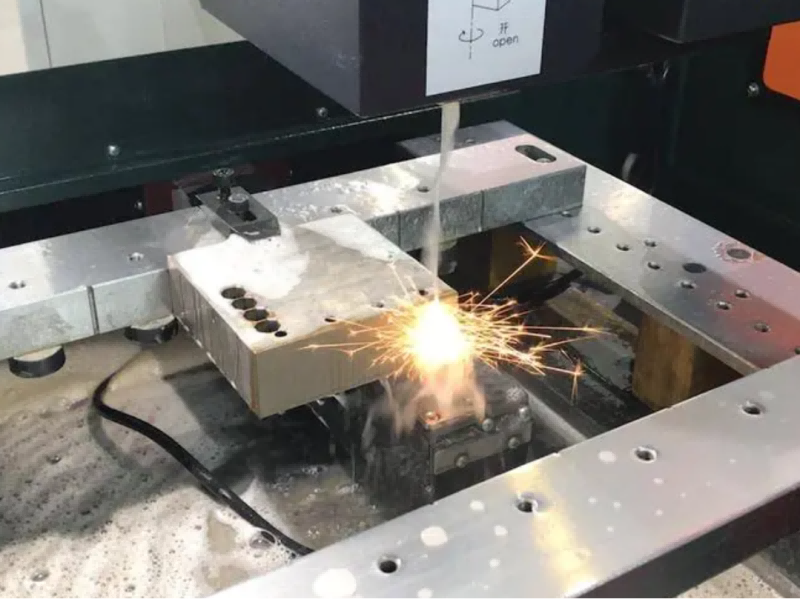

Machining Workshop

KEMING workshop must have mechanical equipment like CNC machines, lathes, grinders, EDM, plus testing tools such as 3D coordinate measurers, optical comparators, and roughness testers.

FAQs About KEMING Castings

How long can l get the feedbacks after we sent the inquiry?

We will reply you within 12 hours in working day.

Are you a direct manufacturer or trading company?

We have two our own casting foundries and one cnc machining factory, we also have our owninternational sales department. We produce and sell all by ourselves.

How about the capacity of your company?

We have 12 modern types of energy-saving & environmentally-friendly production lines including a fullyautomated wax and shell making process flow line, as well as 4 heat treatment production lines and ourannual production capacity is over 20,000 tons.

How many employees of your comany? What about the technicists?

We now have more than 65 emplovees, including 10 enaineers and 50 technicians.

How to guarantee the quality of your goods?

Firstly, we will do the inspection after every process. For the finished products, we will do 100% inspectionaccordina to the customers’ reauirements and the international standard.

Secondly, we have our owntesting lab and the advanced and complete inspection equipment in the casting industry, includingspectrometer, metallographic microscope, tension tester, low temperature tester, x-ray tester, mpt, ut,cmm, video measurement machine and so on.

With these advanced facilities & instruments, we are ableto supply the precise finished products to our customers, and make products meeting their overallinspection reguirements on chemical composition, mechanical properties, non-destructive testing andhigh precise dimensional inspections.

Where are your products mainly exported to?

Our products are mainly exported to over 30 countries such as USA, Germany, Japan, Spain, Italy, UK, Korea, Australia, Canada. Our clients include many oem customers who specialize in train, automobile, forklift and construction machinery. We already have had cooperation with more than 10 of the world’stop 500 companies as one of their major casting suppliers in China

What's the payment term?

When we quote for you, we will confirm with you the way of transaction, fob, cif, cnf, etc. For massproduction goods, you need to pay 30% deposit before producing and 70% balance against copy otdocuments. The most common way is by t/t, l/c is also acceptable.

How to deliver the goods to us?

Usually we will ship the goods to you by sea, because we are in ningbo, and we are only 35 kilometersaway from the ningbo port, it is very convenient and efficient to ship goods to any other countries. Of course, if your qoods are very urgent, the ningbo airport and shanghai airport are also very nearby.