Custom CNC Milling Machining Services

At KEMING, we leverage advanced CNC milling technology and extensive expertise to provide end-to-end solutions tailored to our clients’ needs. Our services include:

- Custom CNC Milling: We handle custom projects with precision, from prototypes to full production runs, accommodating complex geometries and tight tolerances.

- Multi-Axis Milling: Utilizing 3-axis, 4-axis, 5-axis CNC milling machines, we can produce intricate parts with high accuracy and surface finish.

- Material Versatility: We work with a wide range of materials including aluminum, steel, stainless steel, plastics, and more, ensuring the right material for your application.

- Rapid Prototyping: Our rapid CNC milling capabilities enable fast turnaround times, helping clients accelerate product development cycles.

- Low to Medium Volume Production: We offer scalable manufacturing solutions that balance cost and quality, ideal for small batch and medium volume orders.

- Finishing Services: Post-machining treatments such as anodizing, powder coating, plating, and polishing to enhance durability and aesthetics.

- Quality Assurancemeet or exceed industry standards and client specifications.

- Design for Manufacturability Support: Our engineering team provides feedback to optimize designs for CNC milling, improving manufacturability and reducing costs.

Custom CNC Milling Parts by KEMING

What is CNC Milling

CNC milling is a precise subtractive manufacturing process that uses computer numerical control (CNC) to operate milling machines. These machines use rotary cutting tools to remove material from a solid workpiece, such as metal or plastic, to create complex and accurate parts. The process begins with a 3D computer-aided design (CAD) model of the desired part, which is then converted into a CNC program using computer-aided manufacturing (CAM) software. This program guides the milling machine’s movements, controlling the cutting tool’s speed, position, and path along multiple axes to replicate the CAD design with high precision.

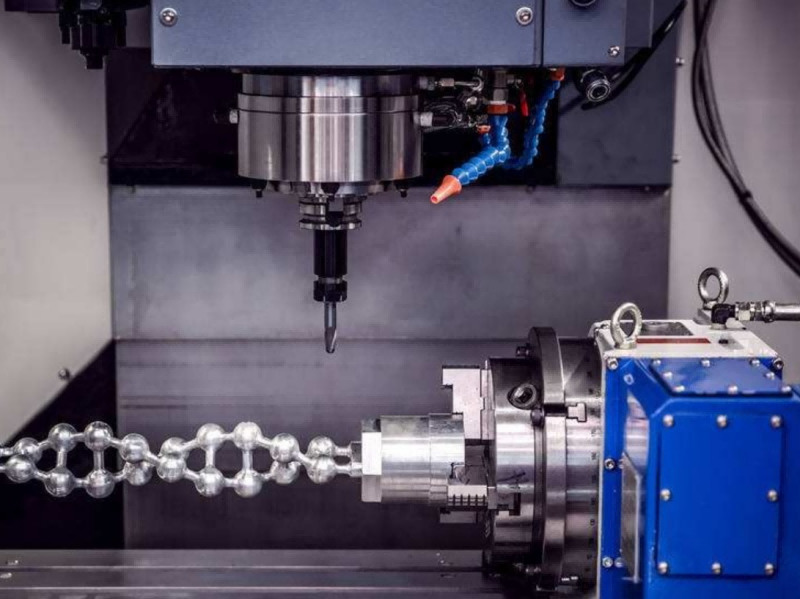

The milling cutter, a rotating cylindrical tool, moves along different axes and angles to cut away material from the workpiece. CNC milling machines can operate in 3-axis, 4-axis, or 5-axis configurations, enabling the production of parts ranging from simple flat surfaces to intricate geometries. The process is highly automated, requiring minimal human intervention once the program is running, which results in consistent quality and efficiency.

The CNC Milling Process by KEMING

At KEMING, we pride ourselves on precision and quality in every part we manufacture. Our CNC milling process is a carefully orchestrated sequence that transforms raw materials into finely crafted components. Whether for prototyping or full-scale production, we are committed to precision, quality, and customer satisfaction.

CAD Design Preparation

The process starts with creating a detailed 2D or 3D CAD model of the part. Our expert team captures every detail, then converts the design into a CNC-compatible file format, ready for programming.

Compatible Code Programming

Using advanced CAM software, we translate the CAD model into G-code—the language that tells our CNC machines exactly how to move the cutting tools. This step is crucial for precision and efficiency.

CNC Machine Setup

Our experienced operators secure the raw material firmly on the milling machine’s worktable. They then select and install the appropriate cutting tools, tailored to the specific requirements of the part.

CNC Milling Machining

The CNC machine takes over, executing the program with high-speed rotation and precise movements. This process removes material layer by layer, shaping the part to exact specifications with exceptional accuracy.

Surface Finishing

To ensure the highest quality, milled parts often undergo finishing processes such as polishing, anodizing, or plating. These steps enhance surface quality, durability, and aesthetic appeal.

Inspection and Delivery

Before delivery, every part is meticulously inspected to verify dimensional accuracy and surface quality. Only parts that meet our stringent standards are packaged and shipped to our customers.

Custom CNC Milling Machining Materials

KEMING CNC milling capabilities extend to a variety of materials, including metals such as aluminum, stainless steel, brass, and titanium, as well as plastics like acrylic, nylon, and polycarbonate. We understand that each material has unique properties and machining requirements. That’s why our experts carefully select the appropriate cutting tools, speeds, and feeds to optimize the milling process and achieve superior surface finishes and dimensional accuracy. Our commitment to quality control and continuous improvement ensures that every part we produce meets or exceeds industry standards.

Metals Used in Custom CNC Milling

- Aluminum Alloys: Aluminum is widely used in CNC milling due to its light weight, machinability, and corrosion resistance. Common alloys include 6061, 7075, 2024, 5052, 6063, 7050, and MIC-6. It’s popular in aerospace, automotive, electronics, and medical devices.

- Stainless Steel: Known for strength and corrosion resistance, stainless steel suits medical, food, marine, and structural uses. Grades like 304, 316/316L, 303, 17-4, 15-5, 416, 420, and 440C are common. Harder to machine than aluminum but very durable.

- Steel Alloys: Types such as 1018, 1215, 4130, 4140, 4340, A2, and O1 tool steels serve structural and tooling roles. Carbon steels offer strength and hardness but can be brittle. Used in automotive, aircraft, tools, and machinery.

- Titanium Alloys: Grades 2 and 5 offer outstanding strength-to-weight ratios and exceptional corrosion resistance, making them highly suitable for demanding applications such as aerospace components and medical implants.

- Copper, Bronze, Brass: Known for excellent electrical conductivity, superior corrosion resistance, and easy machinability, copper alloys such as Copper 101, C110, bronze C932, brass C360, and 260 are commonly used in bearings, bushings, and marine components.

CNC Milling Machining Tolerances

At KEMING, we pride ourselves on delivering high-quality CNC milling services with precise dimensional control to meet your exact specifications. Our typical standard tolerance for CNC milling is around ±0.005 inches (±0.127 mm). This tolerance ensures that the dimensions of your parts can vary slightly within this range without compromising their functionality or performance in most applications.

It is also important to note that different CNC processes have varying standard tolerances. For example, our milling services—whether 3-axis or 5-axis—typically maintain the ±0.005 inches standard. Other processes like router cutting and gasket cutting have their own tolerance ranges, with gasket cutting tolerances generally being wider.

At KEMING, we work closely with you to understand your tolerance requirements and recommend the best machining approach to balance precision, cost, and lead time, ensuring your parts meet the highest standards.

Surface Finishing Options for CNC Milling Parts

- Bead Blasting Sand Blasting: This process uses abrasive media to create a uniform matte or satin finish, removing tool marks and improving surface texture. It is suitable for parts where dimensional tolerances are less critical but a smooth, aesthetically pleasing surface is desired.

- Anodizing: Primarily for aluminum and titanium parts, anodizing creates a hard, corrosion-resistant ceramic oxide layer. Type II anodizing offers a natural matte protective finish, while Type III provides higher wear resistance and hardness for advanced engineering applications. Anodized parts can also be colored for aesthetic purposes.

- Powder Coating: This finish provides a durable, high-impact resistant coating with good corrosion protection and is used when anodizing is not suitable. It offers a range of colors and textures but adds thickness to the part surface.

- Grinding and Polishing: Grinding removes material to refine the surface, producing finishes from rough to mirror-like. Polishing further smooths the surface and can be combined with other finishes to enhance appearance and wear resistance.

- Electroplating: Deposits a thin metallic layer on the part for corrosion protection and enhanced appearance. It is versatile and widely used for conductive metal parts.

Applications of CNC Milling Services

At KEMING, we offer customized CNC milling services for various industries. Our advanced CNC milling technology allows us to produce precise and durable parts tailored to your specific needs. We serve sectors including aerospace, automotive, medical, energy, electronics, and agriculture. Whether you need lightweight aerospace components, accurate automotive parts, sterile medical tools, or durable agricultural machinery pieces, KEMING delivers high-quality solutions with fast turnaround times. Our expert team ensures every part meets strict industry standards for performance and reliability. Choose KEMING for precision, customization, and exceptional service in CNC milling.

Automotive Industry

KEMING supports the automotive sector by producing engine blocks, cylinders, piston rods, water pumps, and lighting components. Our CNC milling guarantees high accuracy and repeatability, making it perfect for original equipment manufacturer (OEM) parts.

Medical Industry

We provide CNC milling for sterile and precise medical equipment. This includes implants, surgical tools, prosthetics, biopsy tubes, bone screws, and mold cavities. Our ability to quickly customize parts helps improve patient care and safety.

Aerospace Industry

We specialize in manufacturing lightweight, high-precision parts including transmissions, fuel bodies, and manifolds. Our advanced CNC milling capabilities enable us to produce complex shapes and hollow components with exceptional accuracy and quality.

Electronics Industry

KEMING produces intricate electronic parts such as circuit board enclosures, heat sinks, RF components, and parts for consumer electronics like smartphones and televisions. Our CNC milling delivers the fine detail and precision required for these small components.

Agriculture Industry

We also serve the agriculture industry by making parts for mechanized equipment, including gearboxes and transmission housings. Our advanced CNC milling processes significantly enhance the durability and operational efficiency of various farm machinery.

Energy Sector

Our CNC milling services help both renewable and non-renewable energy industries by manufacturing valves, turbines, fuel pumps, gears, and gearboxes. Precision and automation in our process ensure that energy system components meet high-quality standards.

Put Your CNC Milling Parts Into Production with KEMING Today

All information and uploads are secure and confidential.