400 series steel investment casting delivers robust and precise components for a wide range of industries. This process utilizes 400 series stainless steel, which offers unique characteristics that distinguish it from other materials.

- 400 series steel investment casting uses stainless steel with a body-centered cubic structure, providing high hardness, exceptional strength, and magnetic properties.

- Containing 11–14% chromium and minimal nickel, 400 series steel investment casting allows for heat treatment to further enhance hardness and durability.

- These features make 400 series steel investment casting ideal for applications requiring wear resistance and magnetic functionality.

KEMING specializes in 400 series steel investment casting, employing advanced techniques to produce reliable stainless steel cast parts for automotive, medical, and industrial machinery sectors. Industries worldwide rely on KEMING for 400 series steel investment casting that meets rigorous quality standards.

Key Takeaways

- 400 series steel investment castings make parts that are strong and hard. These parts are also magnetic. They last a long time and do not wear out easily.

- This steel is great for making parts that need to be exact. It works well for parts with tricky shapes. People use it in cars, planes, medical tools, and machines.

- The lost wax casting process makes parts that are smooth and exact. These parts need less extra work. This process also helps cut down on waste.

- KEMING uses new technology and careful checks to make good 400 series steel castings. These castings are used in many industries.

- Picking 400 series steel depends on how strong the part must be. It also depends on if it will face rust and how much it costs. This makes it a smart pick for hard jobs.

400 Series Steel Investment Casting

400 Series Steel Overview

400 series steel investment casting uses stainless steel alloys from the ferritic and martensitic groups. These stainless steels have chromium as their main ingredient, usually between 11% and 14%. The 400 series is special because it is magnetic, strong, and can be heat treated. Using 400 series alloys in stainless steel investment casting makes parts that are tough, last a long time, and fit together well. Many manufacturers pick these alloys when they need parts that resist wear and some corrosion. Stainless steel casting lets companies make parts with tricky shapes and smooth surfaces. This is why many industries use this process.

Key Properties of 400 Series Steel

400 series steel investment casting gives parts important mechanical properties. These stainless steel alloys are magnetic and can get harder and stronger with heat treatment. Martensitic grades like CA15 and 410 are very strong and resist wearing out. Ferritic grades such as 430 are also magnetic and fight off rust. Stainless steel investment casting with 400 series alloys makes parts that are easy to machine and work well in tough jobs. These alloys are good for making gears, shafts, bushings, valves, and pump parts. The investment casting process makes sure parts are very exact and have smooth surfaces, so less extra work is needed.

Tip: 400 series stainless steel casting is picked for its mix of strength, hardness, and some corrosion resistance. This makes it a top choice for machines and car parts.

Common 400 Series Alloys in Investment Castings

Manufacturers use many 400 series alloys in stainless steel investment casting. Martensitic stainless steels like 410, 416, and 440C are strong, magnetic, and can be heat treated. These alloys are used for knives, turbine blades, and valve parts. Ferritic stainless steels like 409 and 430 resist rust and are used in car exhausts and home appliances. The table below lists some common 400 series alloys and what they are used for:

| Alloy(s) | Key Characteristics | Primary Industrial Uses |

|---|---|---|

| 410, 416 | Martensitic, high strength, good machinability, heat-treatable, magnetic, less corrosion resistant | Automotive parts, food & dairy industries, machine tools, knives, housings, bushings, handles, brackets |

| 418, 420C, 430, 436, 440A, 440C | Martensitic, can be quenched and tempered for hardness, magnetic, wear resistant | Valves, pump shafts, aerospace components, industrial tools, cutlery, blades, turbine blades, fasteners |

Stainless steel investment casting with these alloys gives great corrosion resistance, strength, and long life. This makes 400 series steel investment casting a smart pick for industries that need exact and tough parts.

Stainless Steel Investment Casting Process

Lost Wax Method Overview

The stainless steel investment casting process starts with the lost wax method. First, workers design the part and make a mold from drawings. They fill the mold with wax to make a wax copy of the part. After the wax cools, they take it out and check for problems. Many wax models are put together on a wax tree. This lets them make many parts at once. The wax tree gets dipped in a ceramic liquid and covered with sand. They repeat this step to make the shell strong. When the shell is dry, it goes in an oven. The heat melts the wax and leaves a hollow shell. Hot stainless steel is poured into the shell. When it cools, workers break the shell to get the part out. They cut and smooth the parts as needed. This process makes parts with tricky shapes and smooth surfaces. It works well for 400 series stainless steel.

Quality Control in Stainless Steel Casting

Quality control is very important in stainless steel investment casting. Inspectors check the mold to make sure it is correct. They look at the wax model for cracks or mistakes. Workers watch the temperature and pressure when making the wax model. This helps stop holes from forming. The ceramic shell gets even coats and enough time to dry. This makes it strong. When melting and pouring, workers keep the heat steady and lower impurities. After casting, they use special machines to check the size. They use X-rays and sound waves to find hidden problems. Tests check the strength and makeup of the stainless steel. These steps make sure each part is strong and works well.

KEMING’s Investment Casting Capabilities

KEMING uses new technology to make great stainless steel castings. They use special machines and lasers to measure parts exactly. X-rays and CT scans help find hidden problems inside the parts. KEMING uses vacuum investment casting to make better parts. They use 3D printed patterns for flexible and accurate designs. CNC machines help make smooth and exact parts. KEMING follows world standards like ISO 9001:2015 and AS9100 Rev D. Their careful checks and modern tools make KEMING a top company for stainless steel casting in many industries.

Applications of 400 Stainless Steel Investment Castings

Automotive

Car makers use 400 series stainless steel investment castings for tough parts. These parts must handle a lot of stress and wear. Gears, bushings, brackets, and housings often use 410 stainless steel. This alloy is strong and lasts a long time. It also resists rust, which is important for cars in bad weather. The investment casting process makes it easy to create tricky shapes and thin walls. This means less extra work is needed. These exact parts help make cars and trucks safer and more reliable. KEMING gives car companies castings that meet strict rules. This helps cars work well and last longer.

410 stainless steel investment castings make strong, tough parts. They keep working even when things get hard. This helps cars stay safe and last longer.

Aerospace

The aerospace industry needs parts that are light, strong, and reliable. 400 series stainless steel, like 410 and 416, is a good choice. These alloys are used for jet engine parts, turbine blades, and supports. These parts must be very exact and fit tight spaces. They also need to handle high heat and stress.

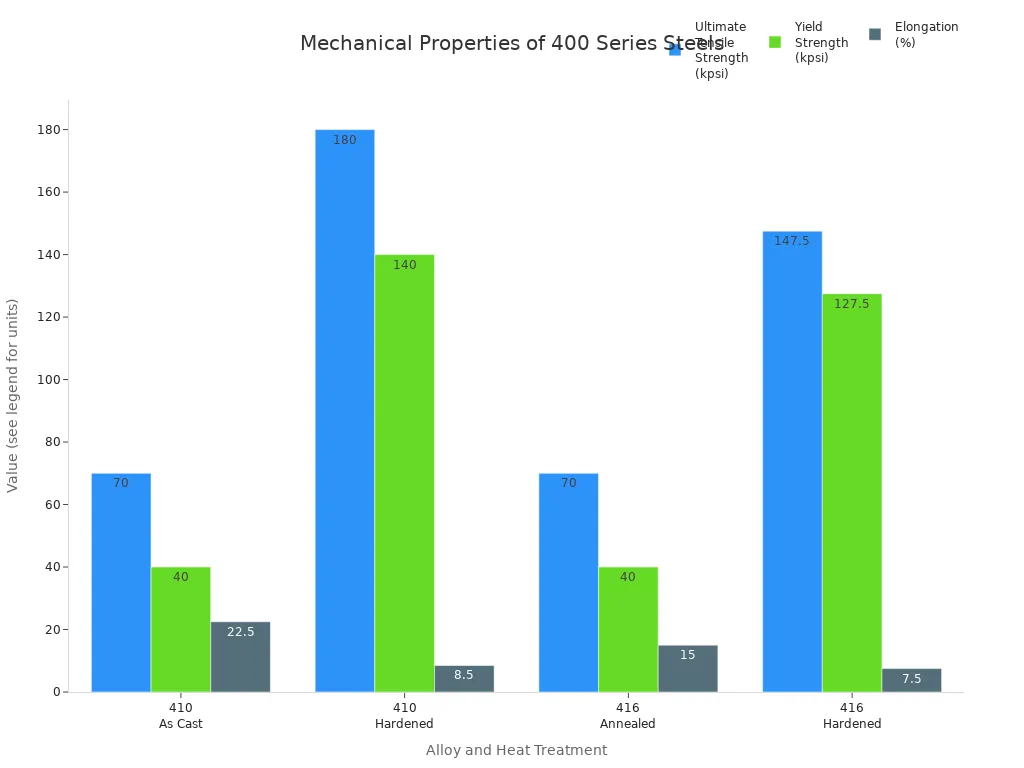

| Alloy | Heat Treatment | Ultimate Tensile Strength (kpsi) | Yield Strength (kpsi) | Elongation (%) | Hardness |

|---|---|---|---|---|---|

| 410 | As Cast | 65-75 | 35-45 | 20-25 | Rb 100 Max |

| 410 | Hardened | 160-200 | 120-160 | 5-12 | Rc 32-45 |

| 416 | Annealed | 65-75 | 35-45 | 12-18 | Rb 100 Max |

| 416 | Hardened | 95-200 | 95-160 | 3-12 | Rc 20-40 |

- 400 series stainless steel is used for:

- Jet engine blades

- Turbine vanes

- Fasteners

- Structural supports

These parts are strong and resist wearing out. They also fight rust and last a long time. The investment casting process makes sure each part is just right. KEMING uses special skills and checks to make safe airplane parts.

Medical

Medical tools and devices need to be strong and easy to clean. 400 series stainless steel, like 410 and 420, is used for these jobs. These alloys are used for surgical tools, dental forceps, and bone implants. They are hard, resist rust, and do not wear out fast. The investment casting process makes smooth and exact parts. This is important for keeping things clean and working well.

- Good things for medical use:

- Stays sharp for cutting tools

- Does not rust in hospitals

- Can be cleaned many times

- Easy to wash and does not react

The smooth surface of medical stainless steel stops germs from sticking. This helps keep hospitals and clinics safe from infections.

Energy & Petrochemical

Energy and petrochemical companies use 400 series stainless steel investment castings for pumps, valves, and fittings. These parts work in tough places with high heat, pressure, and chemicals. 410 stainless steel is tough and does not wear out fast. It also resists some rust. Investment castings make these parts exact and strong.

- Common parts include:

- Pump impellers

- Valve bodies

- Heat exchanger parts

400 series stainless steel stands up to harsh chemicals and high heat. The chromium in the steel makes a shield that stops rust and damage. KEMING’s castings meet the tough rules for oil and gas work. This keeps things safe and running well.

Food & Appliances

Food and appliance makers pick 400 series stainless steel investment castings for their strength and cleanliness. The process makes one-piece parts with no sharp edges or cracks. This makes them easy to clean and keeps germs away. Special surface treatments make them even cleaner and harder to wear out.

| Application Area | Components Manufactured Using 400 Series Stainless Steel Investment Castings |

|---|---|

| Food Processing | Gearbox housings, output flanges, cover plates, clips, arms, auger plates |

| Appliances | Various appliance components |

These castings can be cleaned often and handle hot and cold changes. They meet the strict rules for food safety. KEMING makes sure each part works well and lasts a long time.

Industrial Equipment

Industrial machines use 400 series stainless steel investment castings for parts that get a lot of use. Common parts are drill bit inserts, chipper blades, impellers, gear housings, jaw plates, and crusher parts. Grades 410 and 416 are picked because they are strong and easy to shape.

- Benefits for machines:

- High wear resistance makes parts last longer

- Strong parts help with hard jobs

- Investment casting makes tricky shapes and tight fits

- Less waste and saves money

The high carbon and heat-treatable 400 series stainless steel is great for tools and machines that face friction and hits. This toughness is needed for mining, building, and defense work.

400 series stainless steel investment castings are also used in ships and defense. They are strong, last long, and work well. These alloys help many industries by making parts that are tough and reliable.

400 Series vs Other Stainless Steels

400 Series vs 300 Series

The 400 series and 300 series stainless steels are different. The 400 series has ferritic and martensitic types. These grades have more carbon and chromium. Many 400 series grades are magnetic. They can be heat treated to get stronger. They are good at resisting wear and usually cost less than 300 series. The 300 series is austenitic and not magnetic. These grades have more nickel. This makes them better at fighting rust and staying tough. They are easier to shape and cut. Many companies use 300 series stainless steel for food, medical, and chemical tools because it stays clean and does not rust.

- 400 Series Stainless Steels:

- Ferritic and martensitic types

- More carbon and chromium

- Magnetic

- Can be heat treated for strength

- Not as good at fighting rust

- Costs less

- 300 Series Stainless Steels:

- Austenitic, not magnetic

- Lots of nickel

- Great at fighting rust

- Easier to shape and cut

- Used in tough or clean places

400 series stainless steel is best for strong parts that need to last. 300 series is better for parts that must fight rust and chemicals.

Consider When Selecting 400 Series Versus Other Stainless Steels

Picking the right stainless steel depends on many things. The place where the part will be used is very important. If a part needs to be strong or handle stress, the 400 series is a good pick. These grades can be heat treated and are magnetic, which helps for some jobs. If the part will touch strong chemicals or saltwater, the 300 series is better at fighting rust. Welding is different, too. The 300 series is easy to weld. The 400 series can be harder to weld. Cost matters as well. The 400 series is usually cheaper but may need more care in tough places.

| Factor | 300 Series | 400 Series |

|---|---|---|

| Corrosion Resistance | Better | Not as good |

| Strength | Medium | Higher |

| Magnetic | No | Yes |

| Weldability | Very good | Okay to not so good |

| Cost | More expensive | Cheaper |

| Typical Use | Food, medical, marine | Cars, tools, valves |

Tip: Always pick the right stainless steel for the job. Think about where it will be used, how strong it needs to be, and the cost before you decide.

400 series stainless steel investment casting makes strong and light parts. These parts are used in many industries. The process can make shapes with lots of detail. It also means less cutting and shaping is needed. Stainless steel casting helps companies save time and money. This is very helpful for planes and heavy machines. Many people pick KEMING for their stainless steel casting needs. KEMING uses new technology and checks quality carefully. They also make special parts for each customer. Their team helps from the start to the end of each project. KEMING is a trusted partner for good stainless steel casting.

FAQ

What makes 400 series stainless steel suitable for investment casting?

400 series stainless steel is very strong and hard. It does not wear out quickly. These features help parts last a long time. Many companies pick this material because it works well and can be trusted.

Which industries use 400 series steel investment castings the most?

Industries like cars, planes, hospitals, energy, and food use these castings. They need parts that are strong, exact, and last a long time. These parts help their machines and products work better.

How does KEMING ensure quality in investment castings?

KEMING checks each part with special tools. The team follows world rules for quality. They test every part for strength, size, and smoothness. This makes sure each casting is just right for the customer.

Can KEMING produce custom parts with complex shapes?

Yes. KEMING uses the lost wax method and CNC machines. They can make special parts with tricky shapes. The team uses drawings or samples from customers to make each part fit perfectly.

What are the main benefits of choosing investment casting for 400 series steel parts?

Investment casting makes parts smooth and the right size. This process means less extra work and less waste. Customers get strong, dependable parts that fit what they need.