Lost Foam Casting Manufacturer

KEMING is a professional manufacturer specializing in Lost Foam Casting services, based in Ningbo, China. With over 20 years of experience and a modern factory equipped with advanced CNC machining equipment, KEMING provides high-quality, customized Lost Foam Casting solutions tailored to diverse industrial needs.

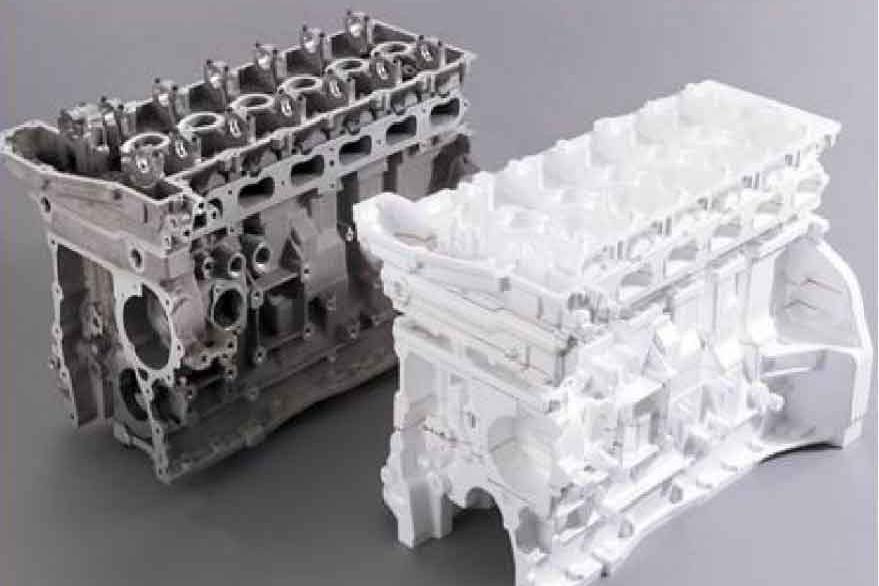

The Lost Foam Casting process at KEMING involves creating precise foam patterns that are coated with refractory material and then embedded in sand. When molten metal is poured into the mold, the foam pattern vaporizes, leaving a detailed metal casting that requires minimal machining. This process allows for complex shapes, excellent dimensional accuracy, and reduced tooling costs, making it ideal for producing intricate parts in various metals such as steel, iron, and alloys.

Why Choose KEMING as Your Casting Manufacturer

- KEMING has over 20 years of experience since its founding in 2003. We can produce lost form castings based on your drawings or samples. With more than 100 raw materials and 5,000 product types, we offer great variety.

- Our modern factory covers over 5,000 square meters and employs 50 skilled workers. We use advanced equipment, including 30 lathes, 10 CNC machines, and two casting lines. We produce over 2,000 tons of evaporative castings yearly.

- KEMING follows strict quality control, meeting global standards like ASTM, DIN, and JIS. We ensure defect-free castings through thorough testing methods. Choose KEMING for reliable, high-quality casting parts.

Lost Foam Casting Materials

Provide by KEMING

KEMING’s lost foam casting process is cost-effective and environmentally friendly. It eliminates the need for cores, reducing labor and tooling costs. The process produces near-net-shape castings with minimal machining, saving time and materials. It also allows for complex geometries and thin walls, enhancing design freedom and performance. KEMING provide high-quality lost foam castings in various metals, including aluminum, cast iron, and ductile iron, each with distinct advantages.

Lost Foam Aluminum

Aluminum castings produced by KEMING are lightweight and have excellent corrosion resistance. Aluminum’s good thermal conductivity and strength-to-weight ratio make it ideal for automotive and aerospace parts. The lost foam process allows for complex shapes with smooth surfaces and tight tolerances, reducing machining costs.

Lost Foam Cast Iron

KEMING provides iron lost foam castings that are renowned for their exceptional wear resistance and superior strength. Cast iron is widely used in heavy machinery and automotive engine components. The lost foam method helps achieve intricate designs and reduces defects like porosity, resulting in durable, high-quality castings.

Ductile Iron Casting

Ductile iron casting parts from KEMING combine the toughness of steel with the castability of iron. They have superior impact resistance and flexibility compared to traditional cast iron. Using lost foam casting, KEMING produces parts with precise dimensions and excellent surface finish, suitable for industrial and automotive applications.

Lost Foam Casting Process

KEMING Lost Foam Casting services emphasize quality and efficiency, supported by ISO9001 certification and a commitment to “Made in China” excellence. Our capabilities include producing castings with tight tolerances, complex geometries, and superior surface finishes.

Pattern Design & Assembly

A foam pattern of the part is made from expanded polystyrene (EPS) using molds or CNC machining for precise shape. It’s attached to a sprue, forming an assembly that often includes gating and risers to guide molten metal flow and allow gas escape during casting.

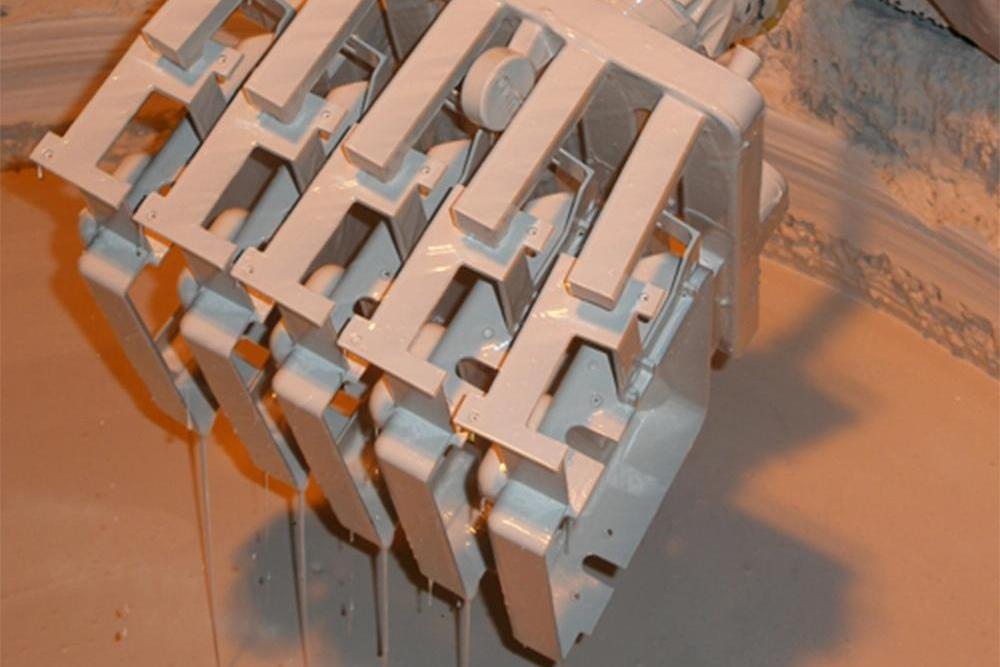

Applying Insulation Painting

The assembled foam pattern is coated with a refractory material to create a shell around the foam pattern. This shell serves as the mold for the casting. The refractory coating is applied through various methods such as dipping, spraying, or brushing to achieve the desired thickness and strength.

Placing the Pattern Into the Sand Flask

Multiple coated foam patterns are assembled together to form a cluster, which is then placed in a flask. The flask is filled with sand or another support material to maintain structure throughout the casting process, ensuring the patterns stay stable until the mold is formed.

Pouring the Molten Metal

The foam pattern and shell mold cluster are set in a flask, then molten metal is poured in. The metal’s heat vaporizes the foam, which escapes through the shell, creating a cavity. The molten metal fills this cavity and solidifies, forming the final casting inside the refractory shell.

Collecting the Lost Wax Castings

After the metal solidifies, the refractory shell is broken off, and the casting is taken out. Remaining foam is removed by shakeout. The lost wax casting can then be finished by grinding, machining, and surface treatments to ensure precise dimensions and a smooth surface.

Lost Foam Casting in Different Industries

Our advanced technology and skilled team ensure every casting is reliable and cost-effective.

Automotive Industry

Construction Industry

Aerospace Industry

Consumer Electronics

Advantage of Lost Foam Casting

High Dimensional Accuracy and Complex Geometry

Lost foam casting creates intricate, accurate parts by expanding polystyrene foam patterns to fill molds completely. It enables complex shapes, internal passages, and thin walls as one piece, eliminating assembly and minimizing post-casting machining for efficient net-shape production.

Reduced Machining and Assembly Steps

Lost foam casting can produce near-net-shape parts with integrated assemblies, it significantly reduces the need for additional machining, finishing, and assembly processes. This decreases labor costs and manufacturing time, as well as the amount of metal used, reducing material waste.

No Need for Draft Angles or Parting Lines

Unlike traditional casting methods that require draft angles and parting lines to remove the pattern, lost foam casting uses foam patterns that vaporize during casting. This eliminates the need for draft and parting lines, allowing for more design freedom and more precise castings.

Environmental and Cost Benefits

Lost foam casting consumes less water and energy than methods like green sand casting. It generates considerably less waste and harmful emissions, while also enabling easier sand recovery and recycling processes. This leads to lower environmental impact and potential cost savings over time.

Simplified and Flexible Process

The entire process is relatively straightforward and highly automated, allowing for significantly shorter lead times. Additionally, it offers the capability to store patterns securely for several months. This flexibility supports both prototyping and mass production with consistent quality.

FAQs About Lost Foam Casting

Is lost foam casting better than sand casting

Lost foam casting offers several advantages over traditional sand casting. It provides higher productivity with fewer defects like core shifting and surface flaws, leading to better yield rates.

LFC is ideal for complex, detailed parts with smooth surface finishes and tight dimensional tolerances, unlike sand casting which is better for simpler, larger parts but has rougher finishes.

However, LFC has higher upfront costs due to foam pattern making but reduces post-casting machining since draft angles are not needed.

For reliable lost foam casting services, KEMING is a recommended supplier known for quality and precision in complex castings. We can help you achieve excellent results with lost foam casting technology.

Is lost foam casting expendable

Yes, lost foam casting is an expendable process. It uses a foam pattern that is destroyed during casting. The foam pattern is made of polystyrene and evaporates when molten metal is poured into the mold. However, used foam patterns can be shredded into small pieces and then reprocessed to create new foam patterns, enabling recycling within the lost foam casting process. Additionally, it is reported that recovered foam can be reused more than 95% of the time, highlighting the efficiency and sustainability of foam reuse in this casting method. This reuse helps reduce waste and supports energy recovery when foam waste is incinerated, further minimizing environmental impact.

What is the cost of lost foam casting

The cost of lost foam casting depends on several factors. These include the size and complexity of the part, the type of metal used, and the production volume. Lost foam casting can save money by reducing machining and assembly steps. However, the initial cost of making foam patterns and molds can be higher than traditional methods. For small runs, the cost per part may be higher. For large production, costs usually decrease due to efficiency. Overall, lost foam casting offers a good balance of cost and quality, especially for complex shapes and medium to large production runs.