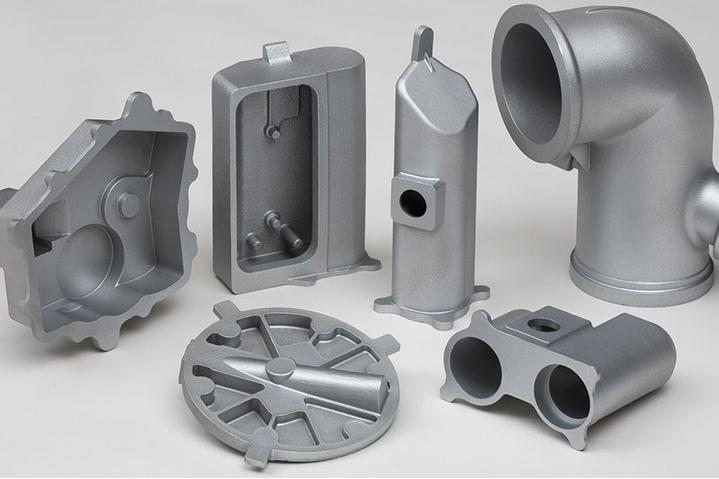

Lost Wax Casting Service

KEMING is a manufacturer that specializes in making high-quality metal parts using the lost wax casting process. Lost wax casting is an ancient method that allows the creation of detailed and precise metal shapes. KEMING has over 20 years of experience and uses modern technology to produce excellent castings for different industries.

KEMING offers a wide range of casting services. We work with many metals, including stainless steel, aluminum, alloy. Our skilled team can handle both small and large orders, from simple shapes to complex designs.

You can send your designs or drawings, and KEMING will help with mold making, casting, finishing, and inspection. This makes KEMING a reliable partner for companies in industries like automotive, aerospace, machinery, and art.

Lost Wax Casting Materials

Provide by KEMING

At KEMING, customers can choose from over 100 kinds of metal materials, including aluminum, steel, stainless steel, and many others. These materials are chosen for their strength, durability, corrosion resistance, and other important properties. This variety allows KEMING to meet the needs of different industries and applications. All materials meet strict quality standards to ensure reliable and consistent casting results. KEMING offers expert advice to help customers select the best material for their project.

Aluminum Casting

Aluminum is lightweight, strong, corrosion-resistant, easy to cast, with excellent thermal and electrical conductivity. KEMING offers various grades for precise castings in automotive, aerospace, and consumer products.

Steel Casting

Steel is a strong and durable metal that is popular in many industries. KEMING offers different types of steel, including carbon steel and alloy steel, ideal for tough parts. Lost wax steel castings serve machinery, tools, structures.

Stainless Steel Casting

Stainless steel resists corrosion and rust, ideal for durable parts. KEMING provides several grades of stainless steel, such as 304 and 316, which are commonly used in medical devices, food processing, and marine equipment.

KEMING Surface Treatments for Lost Wax Castings

KEMING offers a wide range of post-processing surface treatment technologies for Lost Wax Casting products. These treatments improve the appearance, durability, and performance of metal castings. Each method is carefully chosen to meet different customer needs and application requirements.

Galvanized Finish

The galvanized finish involves coating the metal surface with a layer of zinc. This process protects the lost wax castings from rust and corrosion, especially in outdoor or humid environments. It also gives the metal a shiny, silver-like appearance. Galvanizing is ideal for parts that need long-lasting protection without frequent maintenance.

Painted Finish

Painting is a popular surface treatment that adds color and extra protection to castings. KEMING uses high-quality paints that adhere well to metal surfaces. Painted finishes not only improve aesthetics but also help prevent corrosion and wear. Customers can choose from a wide range of colors and textures to suit their design preferences.

Machined Finish

Machining is a precise process that removes excess material from the casting surface. This finish ensures tight tolerances and smooth surfaces where parts need to fit or move together. KEMING uses advanced CNC machines to achieve accurate and consistent results. Machined finishes are often used for functional components requiring exact dimensions.

Powder Coated Finish

Powder coating is a dry finishing process where powdered paint is applied electrostatically and then cured under heat. This method creates a tough, durable coating that resists chipping, scratching, and fading. Powder coated finishes are environmentally friendly and provide excellent protection for metal castings used in harsh conditions.

Polishing and Buffing

Polishing and buffing are finishing techniques that create a smooth and shiny surface on metal castings. Polishing removes surface imperfections, while buffing uses a soft wheel to enhance the shine. These finishes are often used for decorative parts or products requiring a mirror-like appearance.

Shot Blasting and Sand Blasting

Shot blasting and sand blasting are abrasive cleaning techniques. They remove surface impurities, rust, and old coatings by blasting small particles at high speed onto the casting. These processes create a clean, textured surface that improves paint or coating adhesion. They also enhance the overall appearance of the casting.

Uses of Lost Wax Casting Parts

KEMING is a trusted partner for Lost Wax Casting services across multiple industries. From automotive and aerospace to medical, and industrial equipment, KEMING provides precise, high-quality metal parts that meet demanding standards. Our combination of skilled craftsmanship, advanced technology, and customer focus makes us a top choice for companies needing reliable Lost Wax Casting solutions.

Automotive Industry

Medical Devices

Industrial and Engineering

Other Industries

KEMING Quality Control for Lost Wax Castings

KEMING ensures the quality control of Lost Wax Castings through a comprehensive and systematic approach that covers every stage of the production process.

Raw Material Inspection

KEMING starts by carefully inspecting raw materials. They verify the chemical composition and physical properties of metals to ensure they meet required standards. This step is crucial because the quality of the final casting depends heavily on the quality of the raw materials used.

Wax Pattern Quality Control

The wax patterns, which form the basis of the cast, are thoroughly checked for dimensional accuracy and surface condition. Any imperfections in the wax pattern can lead to defects in the final casting, KEMING uses precise measuring tools and visual inspections to ensure patterns are flawless.

Ceramic Shell Inspection

The ceramic shell that encases the wax pattern undergoes a thorough inspection for cracks, uniformity, and completeness. KEMING performs visual inspections and uses non-destructive testing methods like ultrasonic testing to detect any internal defects in the shell.

Post-Casting Inspection

After casting, KEMING conducts multiple inspections. Visual inspection identifies surface defects such as cracks, air holes, or shrinkage cavities. Advanced non-destructive testing methods like X-ray radiography and ultrasonic testing detect internal flaws such as inclusions or porosity.

Lost Wax Casting Process

KEMING is a professional manufacturer specializing in lost wax casting. Lost wax casting is a method where a metal part is made by pouring molten metal into a mold created from a wax model. This process allows for very detailed and accurate metal parts, suitable for complex shapes and fine details. Below is a introduction to the KEMING lost wax casting process.

Lost Wax Casting Mold Making

First, engineers design and create precise moulds. These moulds shape the wax models and ensure the final metal parts have the correct dimensions and details.

Wax Model Spraying & Tree Building

Liquid wax is sprayed into the moulds to form wax models. These models are then attached together on a central wax stem, forming a structure called a “tree.”

Rinsing the Wax Trees

The wax trees are carefully rinsed with water to remove any dirt or dust. This helps ensure the ceramic layers will stick properly during the next steps.

Building Ceramic Layers

Multiple layers of ceramic slurry and fine sand are applied to the wax trees. Each layer dries and hardens, creating a strong shell around the wax models.

Autoclave & Sintering

The ceramic-coated wax trees are placed in an autoclave. High pressure and temperature remove all moisture and strengthen the ceramic shell through sintering.

Molten Metal Casting

The wax inside the ceramic shell is melted out, leaving a hollow space. Molten metal is then poured into this cavity to form the final metal parts.

Break the Ceramic Shell

Once the metal cools and solidifies, the ceramic shell is carefully broken away, revealing the rough metal castings inside.

Blasting, Grinding and Visual Inspection

The metal parts are cleaned using blasting and grinding to remove ceramic residues and surface imperfections. Each casting is visually inspected for defects.

Machining, Heat and Surface Treatment

Castings undergo machining to achieve precise dimensions. Heat treatment improves metal properties, and surface treatments enhance appearance and corrosion resistance.

Final Quality Control Inspection

The finished parts go through a thorough quality check. Measurements, strength tests, and surface inspections ensure they meet all required standards before delivery.