Precision Machining

At KEMING, we understand the importance of precision, reliability, and efficiency in modern manufacturing. Our precision machining services combine advanced CNC machining with metal casting to deliver superior parts. We start with metal investment casting to create the basic shape of the component. Then, our state-of-the-art CNC machining facility refines every detail, ensuring high accuracy and excellent surface finish.

This hybrid approach allows us to produce complex parts with intricate features that other methods cannot achieve. Our in-house capabilities mean faster turnaround times and consistent quality control. Whether you need investment cast parts or fully finished components, KEMING guarantees precision and reliability in every piece. Choose KEMING for precision machining services that meet the highest industry standards and help your business stay competitive.

Precision Machining Processes by KEMING

Keming offers a wide range of precision machining processes to meet diverse customer needs. Our equipment includes over 50 CNC machines, grinding machines, laser cutting, and automatic welding robots. Our advanced CNC machines enable precise milling, turning, and grinding with tight tolerances and high dimensional accuracy.

CNC Milling Machining

At KEMING, we offer professional CNC milling services to meet your precise manufacturing needs. CNC milling uses rotating cutting tools to remove material from solid metal blocks. This process creates complex shapes, features, and smooth surfaces with high accuracy. Our advanced 3-axis, 4-axis, and 5-axis milling machines handle intricate geometries like gears, slots, and contours.

We use various cutting tools to ensure your parts meet exact dimensions and quality standards. Whether you need prototypes or production runs, KEMING’s CNC milling delivers reliable, efficient, and precise results every time. Trust us to bring your designs to life with expert craftsmanship.

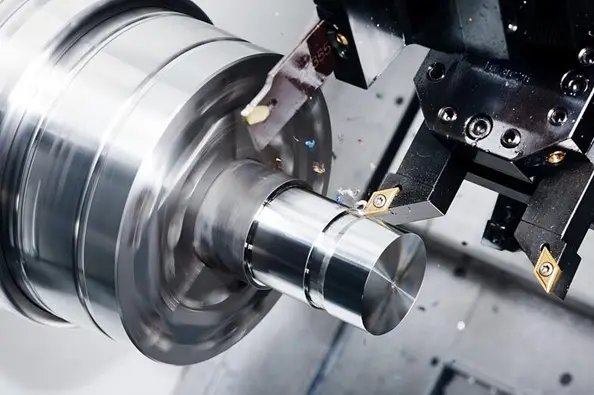

CNC Turning Machining

At KEMING, we offer expert CNC Turning services to create precise round-shaped parts. Our process involves rotating metal bars or tubes on a lathe while cutting tools remove material. This allows us to produce parts like shafts, rods, and other components with perfect circular shapes. We use techniques such as boring, grooving, and facing to achieve high accuracy and smooth finishes.

CNC Turning is ideal for parts with rotational symmetry. With KEMING’s advanced machines and skilled team, we ensure quality, efficiency, and fast delivery for your manufacturing needs. Trust KEMING for reliable CNC Turning solutions.

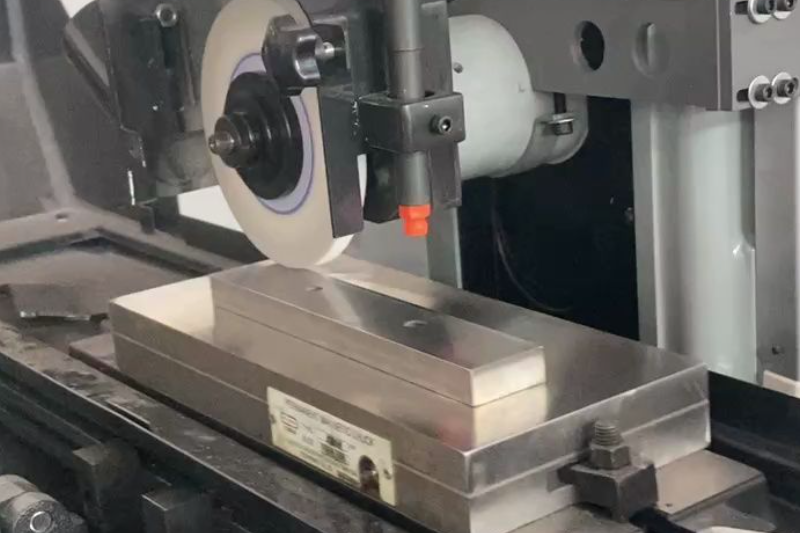

CNC Precision Grinding

At KEMING, we offer expert CNC Grinding services to meet your high-precision machining needs. Our CNC grinders use advanced abrasive wheels to carefully remove material from your workpieces. This process ensures very fine surface finishes and tight tolerances. We specialize in grinding hardened materials and parts that require exact dimensions and superior surface quality.

Our machines can smooth surfaces to a roughness value as low as 0.8 μm, delivering polished or even mirror-like finishes. Trust KEMING for precise, reliable, and high-quality CNC grinding solutions tailored to your manufacturing demands.

CNC Drilling Machining

At KEMING, we offer expert CNC drilling services to meet your precise manufacturing needs. Our CNC drilling uses a rotating drill bit to create accurate holes with exact depths and diameters in various materials. We specialize in techniques like spot drilling, which starts with a shallow hole to ensure exact positioning, and peck drilling, ideal for deep holes by clearing chips and reducing heat.

With advanced CNC machines, KEMING ensures high-quality, efficient, and reliable drilling for your projects. Trust us for precise holes that fit your specifications perfectly.

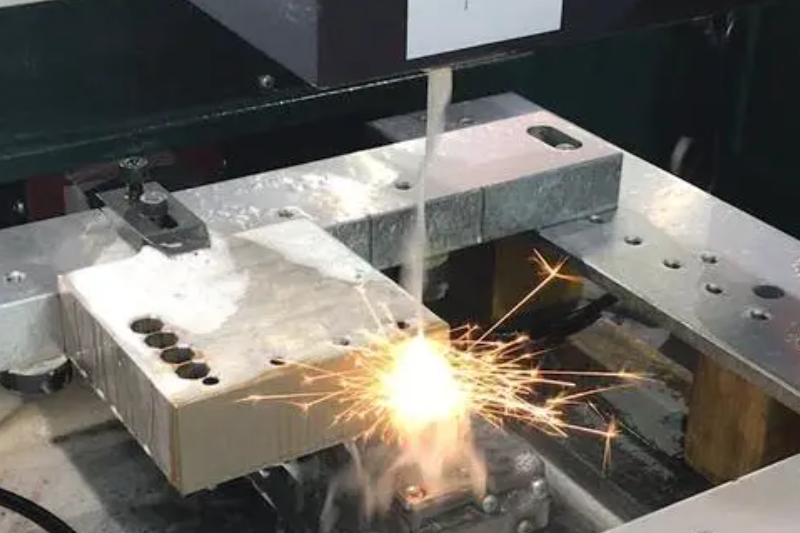

Electrical Discharge Machining

At KEMING, we offer expert Electrical Discharge Machining (EDM) services. EDM is a precise, non-contact process that uses electrical sparks to remove material from electrically conductive metals. This method is perfect for cutting hard metals like titanium and tungsten, which are difficult to machine with traditional tools.

Our EDM technology allows us to create complex shapes and fine details with high accuracy and repeatability. Because the process uses electrical discharges instead of mechanical force, it causes minimal stress on the workpiece. Choose KEMING for reliable, high-quality EDM solutions tailored to your needs.

Gallery of Precision Machining Partsby KEMING

Why Choose KEMING for Precision Machining Services

Extensive and Advanced Equipment

KEMING's workshop features 10 advanced CNC machines, 50 CNC machines, 2 grinding machines, 1 laser cutter, and 2 welding robots, enabling diverse machining tasks from precise components to large-scale production.

Commitment to Quality and Precision

KEMING emphasizes quality, precision, and customer satisfaction, supported by a skilled workforce and state-of-the-art equipment, positioning it as a reliable partner for complex and varied precision machining needs.

Expertise in Material Processing

KEMING demonstrates proficiency in processing castings and profiles with a focus on cold processing, which allows efficient machining without excessive heat, preserving the material properties of the workpieces.

Customization and Versatility

KEMING can tailor its precision machining services to meet specific client requirements, ensuring high-quality parts with tight tolerances and complex geometries produced via CNC mills, turning centers, or drills.

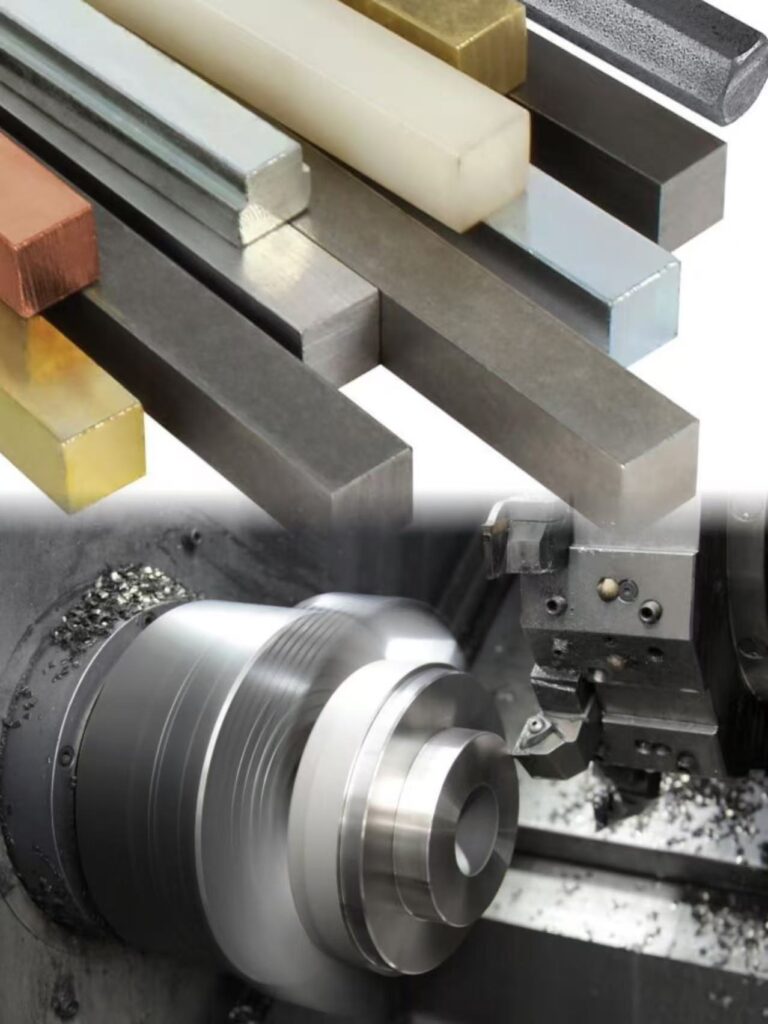

KEMING offer CNC precision machining in a wide range of materials to meet your product requirements

Aluminum Alloys

We work with various aluminum alloys such as AL6061, AL6063, AL6082, AL7075, AL5052, and A380. Aluminum is a lightweight metal that is highly ductile and easy to machine. Its excellent strength-to-weight ratio makes it ideal for use in aerospace, automotive, and electronics industries where performance and durability are critical.

Stainless Steel Alloys

We machine stainless steel alloys such as SS201, SS301, SS303, SS304, SS316, and SS416. These materials are known for their corrosion resistance, strength, and durability. Stainless steel is ideal for applications requiring high hardness and excellent wear resistance, though it can be challenging to machine, often needing high-speed cutting tools.

Steel Alloys

Our steel alloy machining services cover a variety of grades including 1018, 4140, 1045, A2, and D2. These steel alloys offer outstanding fatigue resistance, high tensile and yield strength, as well as excellent abrasion resistance. They are extensively used in manufacturing machinery components, precision tooling, and various structural applications.

Mild Steel

We also machine mild steel, which is commonly represented by grades such as A36. Mild steel is widely appreciated for its excellent weldability, moderate tensile strength, and cost-effectiveness. Due to these properties, it is frequently utilized in various applications including construction projects, as well as in the manufacturing of jigs and fixtures.

Copper Alloys

Our copper alloy options include C11000, C12000, and C36000, each offering unique properties. Copper is highly valued for its excellent thermal and electrical conductivity, as well as its high ductility and strong corrosion resistance. It is easy to weld, but due to its low hardness, careful machining is necessary to prevent tool jamming and ensure precision.

Applications of CNC Precision Machining

KEMING specialize in producing highly accurate parts with tight tolerances, often as precise as ±0.001 inches, which standard machining cannot achieve. Our advanced CNC machines and tooling enable us to deliver precise components essential for automotive parts, medical implants, aerospace components, and electronics industry. These industries require complex shapes and high surface quality that our CNC milling, turning, and drilling services provide efficiently.

Automotive Industry

We support automotive companies by producing high-quality prototypes and complex parts. Our CNC precision machining enables functional testing and design adjustments before full production, ensuring reliability and performance in modern vehicles.

Aerospace Industry

Safety is critical here. Our machining services produce highly accurate aerospace components. These components include landing gear ports, bushings, manifolds, airfoils, etc. Precision reduces risks and guarantees performance under demanding conditions.

Medical Industry

The medical field demands extremely tight tolerances for devices like implants, orthotic tools, and MRI components. KEMING’s precision machining meets these stringent requirements, delivering parts that ensure safety and functionality.

Electronics Industry

With the trend toward smaller, more powerful devices, KEMING machines compact, lightweight components like semiconductors, heat sinks, circuit boards, and other consumer electronics components. We maintain tight tolerances even for high-volume production runs.

CNC Precision Machining FAQs

What are the tolerances for CNC machined parts?

CNC machined parts usually have standard tolerances around ±0.005 inches (±0.13 mm), which is very precise—about twice the thickness of a human hair. For higher precision, tolerances can be tightened to ±0.002 inches (±0.05 mm) or even ±0.0005 inches (±0.0127 mm) on specific features like reamed holes. The exact tolerance depends on the material, part complexity, and function. Tighter tolerances increase cost and manufacturing difficulty, so they should be specified only where necessary. For reliable, high-quality CNC precision machining with excellent tolerance control, KEMING offers professional services tailored to your needs.

What are your inspection options for CNC machining?

At KEMING, we offer comprehensive inspection options for CNC machining to ensure your parts meet the highest quality standards. Our inspection methods include visual inspection to check surface quality, dimensional inspection using precise tools like calipers and micrometers, and advanced coordinate measuring machines (CMM) for accurate 3D measurements. We also perform surface roughness testing and hardness testing to verify material properties. Additionally, we conduct first article inspections and in-process inspections to catch issues early and ensure consistent quality throughout production. Choose KEMING’s CNC precision machining services for reliable, high-quality parts with thorough quality control.

Can you provide surface finishing for precision machined parts?

At KEMING, we provide high-quality surface finishing for precision machined parts to ensure excellent appearance, tight tolerances, and durability. Our advanced CNC machining capabilities include polishing and shot blasting to achieve smooth and precise surfaces. We use cold processing techniques to maintain material integrity and offer customized finishing based on your needs. With over 50 CNC machines and skilled technicians, KEMING guarantees consistent, reliable results for complex parts. We recommend our CNC Precision Machining services for precision components with superior surface finishes, meeting ISO 9001 standards and customer satisfaction. Choose KEMING for your precision machining and finishing needs.

How to start with precision machining service?

To start with precision machining service, first prepare a 3D CAD file and a 2D CAD drawing with reference dimensions of your component. Specify the desired material, order quantity (annual or one-time), tolerance limits, and surface finish requirements. Choose a reliable provider with advanced equipment and material expertise to ensure quality. KEMING offers excellent CNC precision machining services that simplify the quotation process and deliver high-quality parts with tight tolerances and professional support. Providing these details upfront helps KEMING give you an accurate quote and meet your machining needs efficiently.

Put Your Precision Machining Parts Into Production with KEMING Today

All information and uploads are secure and confidential.