Choosing the right material for agriculture machinery casting parts depends on the specific needs of each farm machine. Steel offers exceptional strength and toughness, while iron is easier to shape and helps reduce vibration. The choice of material impacts the durability, cost, and overall performance of the machinery. The table below highlights how different materials affect agriculture machinery casting parts:

| Material | Durability Impact | Cost Impact | Performance Impact |

|---|---|---|---|

| Carbon Steel | Very strong, can withstand high stress | Moderately priced | Ideal for blades, tines, and frames |

| Stainless Steel | Resistant to rust and corrosion | Saves money on maintenance | Best suited for parts exposed to moisture or chemicals |

| Grey Iron | Easy to cast and reduces vibration | Cost-effective | Commonly used for gearboxes and brake drums |

| Ductile Iron | Strong, flexible, and more rust-resistant | N/A | Perfect for pivots and clutch pins |

For optimal performance, farmers should select agriculture machinery casting parts that match their equipment and operating conditions.

Key Takeaways

- Steel is very strong and tough. It works well for heavy parts like axles and frames. These parts get hit hard and need to be strong.

- Iron, like gray and ductile iron, is easier to shape. It helps lower shaking and costs less. It is good for parts like housings and gearboxes.

- Stainless steel does not rust or corrode. It is best for farm machine parts that get wet or touch chemicals.

- Picking the right material depends on what the part does. It also depends on where it works, how much it costs, and how it is made. This helps the part last long and work well.

- Using good casting methods and heat treatment makes parts stronger. It also helps them last longer. This lets farm machines work better and stay useful for more years.

Key Materials for Agriculture Machinery Casting Parts

Picking the right materials for casting parts is important. It helps machines last longer and work better. It also saves money. Farmers and makers pick materials based on what their machines need. They also think about where the machines will be used. The table below shows what makes each material special and how it is used:

| Material | Defining Properties | Typical Applications in Agricultural Machinery |

|---|---|---|

| Cast Iron | High wear resistance, good machinability, cost-effective | Plough bases, brake drums, gear housings requiring heavy load endurance |

| Steel | Strong, hard, impact resistant, long life, structural integrity | Axles, tractor frames, tiller blades exposed to extreme stress |

| Aluminum | Lightweight, durable, corrosion resistant | Gearbox casings, pump housings, clutch covers, irrigation and fertilisation systems |

| Ductile Iron | Combines strength of steel and castability of iron, more ductile, absorbs stress and vibration | Suspension components, rotating arms, tractor linkage |

| Bronze & Brass | High corrosion resistance, low friction coefficient | Bushings, bearings, fittings in irrigation systems |

Carbon Steel

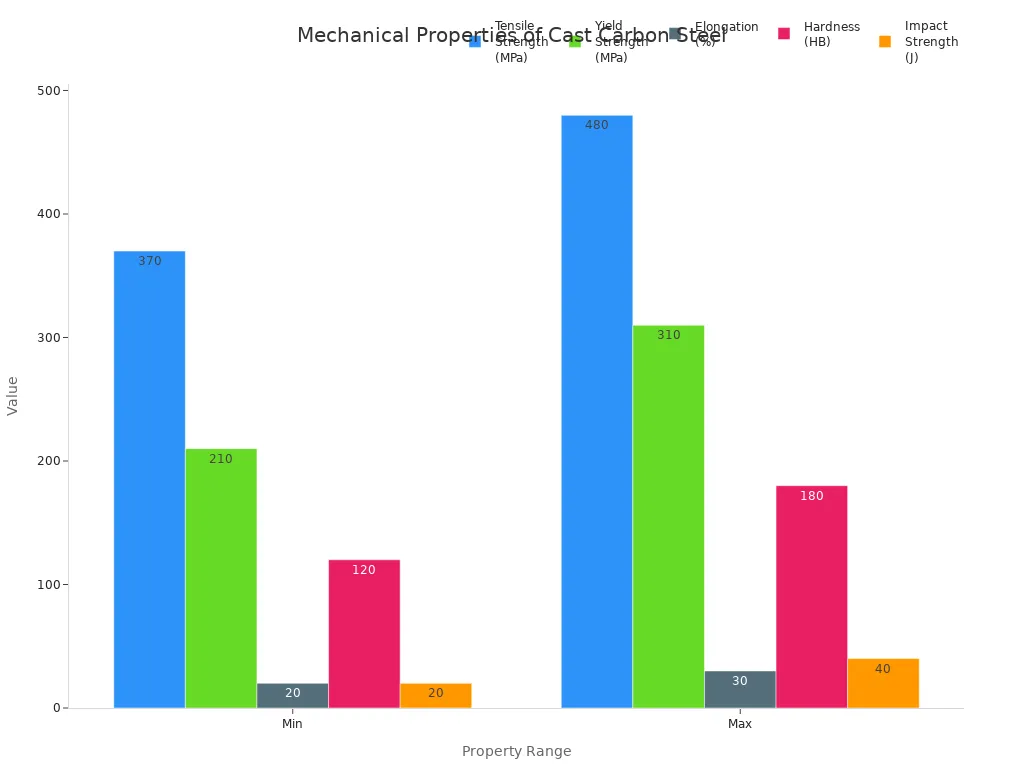

Carbon steel is one of the best materials for farm machinery casting parts. It is very strong and tough. It does not cost too much. Makers use carbon steel to make things like blades and frames. Carbon steel has high tensile strength and yield strength. This means it can handle heavy loads. It is easy to shape, so makers can create complex parts. Heat treatment makes carbon steel even stronger and better. This is why it is a good choice for tough farm jobs.

Gray Iron

Gray iron is still a favorite for casting farm machine parts. It is strong and does not cost a lot. Gray iron can handle a lot of pressure. It also helps stop machines from shaking too much. Farmers use gray iron for engine housings and brackets. It is easy to shape, so parts can be made quickly and cheaply. Gray iron does not change much with heat. It also does not rust easily. This makes it good for parts that need to last a long time.

Ductile Iron for Agricultural Castings

Ductile iron is strong like steel but easy to cast like iron. Its special structure makes it tough and flexible. Ductile iron can take heavy hits and keep working. It is used for tractor linkages and rotating arms. Ductile iron is great for making parts that need to handle stress and shaking. It costs more than gray iron. But it is worth it because it lasts longer and works better for hard jobs.

Stainless Steel and Alloys

Stainless steel and its alloys do not rust easily. This makes them great for farm machines that get wet or dirty. Stainless steel has chromium, which forms a shield to protect it. Makers use stainless steel to make strong and smooth parts. Alloys like 304 and 316 are even better at fighting rust and heat. These materials help make high-quality parts for farm machines. Stainless steel parts fit well and work in tough places.

Tip: Picking the right material and casting method, like investment casting, helps farm machines work well and last a long time.

Performance Comparison of Steel and Iron in Agricultural Machinery Casting Parts

Strength and Toughness

Steel and iron are different in strength and toughness. Steel castings have less than 2% carbon. This gives them high tensile strength and toughness. Heat treatment can make steel even stronger. Steel is a good choice for parts that get heavy loads and impacts. Cast steel can handle sudden shocks and strong forces. This helps machines last longer and work better.

Cast iron, like gray iron, has high compressive strength. It can absorb vibration well. But it is brittle and has low tensile strength. This means it breaks easier and cannot bend much. So, it is used for parts that do not bend or get hit hard. Ductile iron is better than gray iron. It is more flexible and tough. Sometimes, ductile iron can take the place of steel. But steel is still better for parts that need to hold heavy loads and take hits.

| Property | Cast Iron | Steel |

|---|---|---|

| Carbon Content | 2-4% (higher) | Less than 2% |

| Strength Type | High compressive strength | High tensile strength |

| Ductility & Brittleness | Brittle, low ductility | More ductile, less brittle |

| Impact Resistance | Low, prone to fracture under impact | High, excellent impact resistance |

| Toughness | Low toughness (except ductile cast iron) | High toughness, can be enhanced by heat treatment |

| Special Subtypes | Ductile cast iron improves toughness and strength | Can be heat treated to improve properties |

Steel is best for casting parts like axles, tines, and frames. These parts need to hold heavy loads. Iron is good for parts that need to resist compression and stop vibration. These are things like housings and bases.

Wear and Abrasion Resistance

Wear and abrasion resistance are important for farm parts. These parts touch soil, rocks, and other hard things. Steel, like AR400 and AR500, is very good here. These steels last much longer than regular carbon steel or iron. AR400 steel can last two to three times longer. AR500 lasts even longer in tough places.

| Material Type | Hardness (HRC) | Wear Resistance Compared to Carbon Steel | Typical Applications in Agriculture | Service Life Improvement |

|---|---|---|---|---|

| AR400 Steel | 38-45 | 200-300% better than carbon steel | Tillage points, cutting edges, wear plates | Extends service life by 2-3 times |

| AR500 Steel | 48-54 | 40-50% better than AR400 | Highly abrasive soils, premium wear components | Lasts 40-50% longer than AR400 |

| Standard Carbon Steel (e.g., 65 Mn) | N/A | Lower strength and wear resistance | General agricultural components, less abrasive use | Baseline |

| White Cast Iron | N/A | Good wear resistance but less than AR steels | Specific wear parts requiring toughness | Less than AR steels |

| Pearlite Malleable Cast Iron | N/A | Moderate wear resistance | Curved knives, plow parts | Less than AR steels |

Cast iron, like white cast iron, has good wear resistance. It is used for parts like plowshares and curved knives. But it does not last as long as AR steels. Heat treatment and surface hardening can help both steel and iron last longer. Investment casting helps make strong and well-shaped parts. This makes it easier to get good farm parts.

Corrosion Resistance

Corrosion resistance is important for parts that get wet or touch chemicals. Stainless steel is best for this. It has chromium and nickel. These make a layer that stops rust and corrosion. Stainless steel parts work well in irrigation systems and fertilizer spreaders. They are good for machines that get wet or dirty.

Carbon steel and cast iron need coatings to stop rust. E-coating makes a barrier to keep out water and chemicals. This helps steel parts last longer and need less fixing. Galvanized steel has some protection, but if the zinc gets scratched, rust can start. Cast iron has some natural resistance because of graphite. But it still needs coatings to last a long time.

A study showed stainless steel, like 18Cr8Ni alloys, rusts the least. Carbon steels and low-chromium steels rust faster. Stainless steel costs more at first. But it saves money later because it needs fewer repairs.

Side-by-Side Comparison Table

| Property | Cast Iron | Cast Steel |

|---|---|---|

| Carbon Content | 2% – 4% | 0.15% – 2% |

| Mechanical Strength | High compressive strength, brittle | High tensile strength, ductile |

| Heat Resistance | Excellent heat retention, withstands high temperatures | Higher temperature resistance, withstands thermal shocks |

| Wear Resistance | High wear resistance due to graphitic microstructure | Variable, depends on carbon content; hardened steel is abrasion resistant |

| Vibration Damping | Excellent due to graphitic flakes | Poor vibration damping |

| Corrosion Resistance | Slightly better due to graphite and patina | Better in stainless variants, good for moist/outdoor environments |

| Malleability | Brittle, unsuitable for complex shapes | Flexible, suitable for complex and precise shapes |

| Weight | Heavier | Lighter |

| Castability | Easier to cast, lower melting point | Harder to cast, higher melting point and shrinkage |

| Cost | Generally lower | Generally higher |

Note: Cast iron is best for heavy, stable farm machine parts. These parts need to be strong, wear-resistant, and stop vibration. Cast steel is better for parts that need to hold heavy loads, bend, resist rust, and have complex shapes.

Practical Implications for Farm Machinery Use

Picking the right materials for casting farm parts is important. It affects how well machines work, how often they need fixing, and how much they cost. Steel casting parts, made with investment casting, are strong and last a long time. They are great for frames, axles, and parts that get hit a lot.

Iron casting parts, like gray and ductile iron, are good for parts that need to stop vibration and resist wear. These are things like housings and bases. But they may need to be replaced more often if used in high-impact spots. Stainless steel casting parts cost more. But they do not rust and need less fixing for machines that get wet or touch chemicals.

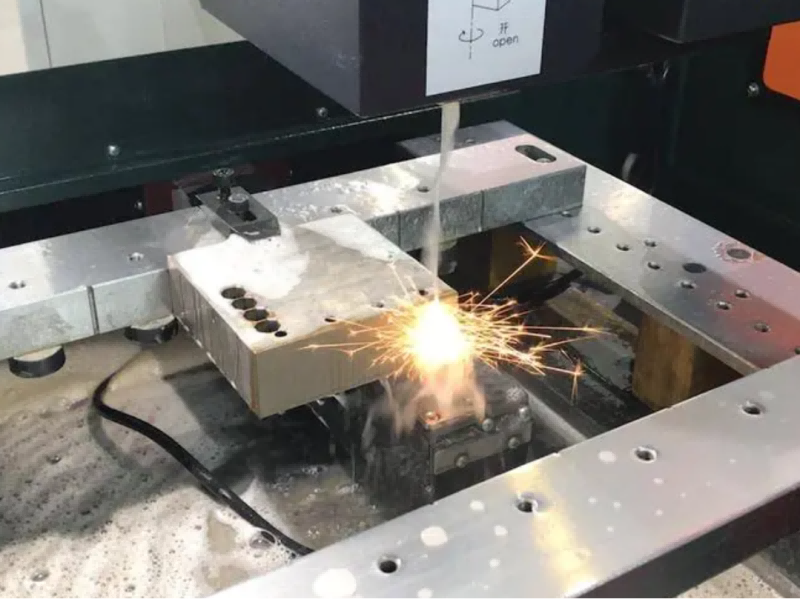

Investment casting helps makers create strong and well-shaped parts. This makes sure farm parts work well and last longer. It also helps machines work better and break down less.

Cost and Availability of Materials

Material Costs

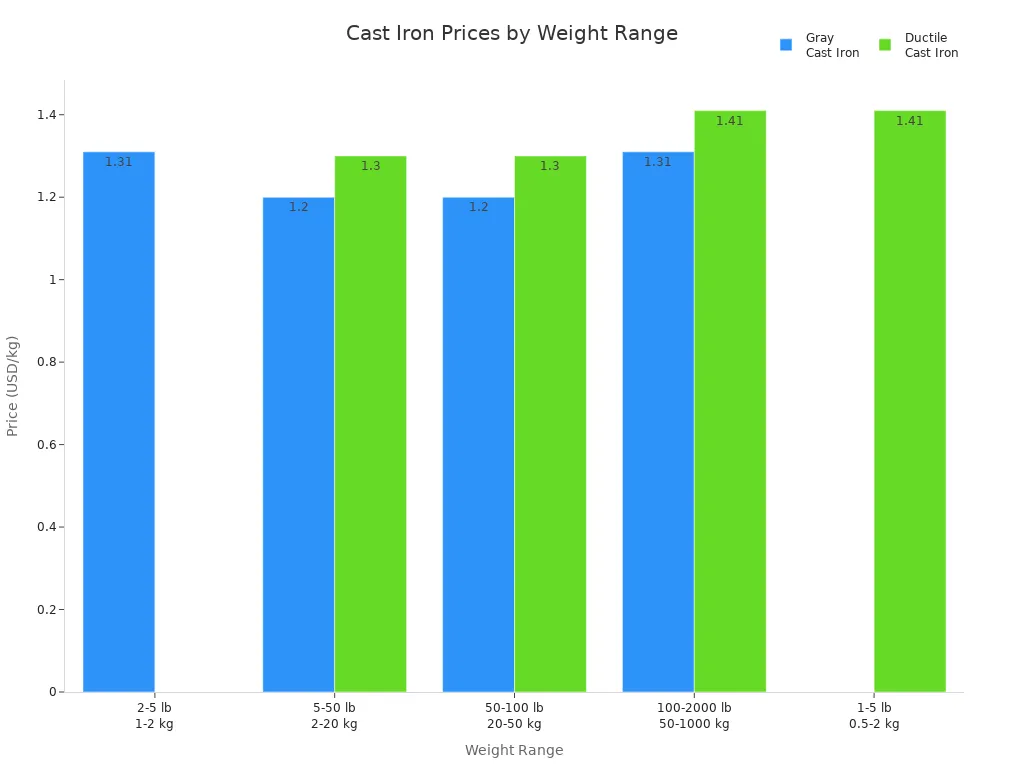

Farmers and makers look at prices before picking materials. Gray iron and ductile iron are popular because they work well and do not cost too much. The price for gray iron sand casting parts changes with how many you buy. For example:

- If you buy 1 to 499 pieces, each costs about $8.5.

- If you buy 500 to 999 pieces, each costs about $6.

- If you buy 1000 to 4999 pieces, each costs about $4.

- If you buy 5000 or more, each costs about $2.

Buying more pieces makes each one cheaper. The table below shows the average price for gray cast iron and ductile cast iron by weight:

| Material Type | Weight Range (lb/kg) | Price (USD/lb) | Price (USD/kg) | Price (USD/ton) |

|---|---|---|---|---|

| Gray Cast Iron | 2 – 5 lb (1 – 2 kg) | 0.60 | 1.31 | 1314 |

| Gray Cast Iron | 5 – 50 lb (2 – 20 kg) | 0.55 | 1.20 | 1203 |

| Gray Cast Iron | 50 – 100 lb (20 – 50 kg) | 0.55 | 1.20 | 1203 |

| Gray Cast Iron | 100 – 2000 lb (50 – 1000 kg) | 0.60 | 1.31 | 1314 |

| Ductile Cast Iron | 1 – 5 lb (0.5 – 2 kg) | 0.64 | 1.41 | 1411 |

| Ductile Cast Iron | 5 – 50 lb (2 – 20 kg) | 0.59 | 1.30 | 1300 |

| Ductile Cast Iron | 50 – 100 lb (20 – 50 kg) | 0.59 | 1.30 | 1300 |

| Ductile Cast Iron | 100 – 2000 lb (50 – 1000 kg) | 0.64 | 1.41 | 1411 |

Steel casting usually costs more than iron casting. Stainless steel and alloy casting can make the price even higher. But these materials can last longer and need less fixing, so they may save money later.

Manufacturing and Supply

Casting materials for farm machines must be easy to get in big amounts. Gray iron and ductile iron are simple to find and can be made into many shapes. They melt at lower heat, so casting is faster and cheaper. Steel casting needs more heat and energy, which can slow things down and cost more.

Makers pick casting methods based on the material and part shape. Investment casting is good for tricky shapes but can cost more. Sand casting is used for big, simple parts and is a cheap choice for many farms.

Note: Both steel and iron casting can hurt the environment. Making these materials uses resources and can cause pollution. Moving and processing raw materials adds to this. Picking the right materials and casting method helps balance cost, performance, and caring for the environment.

Applications in Agriculture Machinery Casting Parts

Best Farm Machinery Casting Parts for Steel

Steel is very important in farm machinery casting parts. Makers pick steel for parts that face a lot of stress. Steel casting gives high strength and hardness. It also helps parts resist impacts. These features help machines work well in hard places. The best steel casting parts for farms are:

- Axles that hold heavy weight and go over rough ground

- Tractor frames that keep the machine strong

- Tiller blades that cut dirt and break up trash

- Engine blocks that handle heat and shaking

- Transmission housings that control power and movement

- Chassis supports that help machines stay steady

- Axle parts that move all the time

Steel casting parts last a long time. They do not bend or break easily. Farmers trust these parts for safety and long use. Steel castings also help farmers work without many stops during busy times.

Note: Steel casting parts are needed for machines that carry heavy loads, shake a lot, and work in tough fields.

Best Farm Machinery Casting Parts for Iron

Iron is still a top pick for many farm machinery casting parts. Iron casting is easy to shape and lasts a long time. It also helps stop shaking. These things make iron good for machines that move over and over and touch rough stuff. The table below lists common iron casting parts and why they are used:

| Type of Iron Casting | Best Farm Machinery Casting Parts | Reasons for Choosing Iron Castings |

|---|---|---|

| Gray Iron Castings | Plowshares, cultivator points, wear parts | Good wear resistance, high damping, cost-effective |

| Ductile Iron Castings | Gears, pulleys, high-stress components | High strength, toughness, ductility, fatigue resistance |

| Austempered Ductile Iron | Gears, sprockets, high-stress parts | Superior strength, toughness, wear resistance |

Iron casting parts are found in gears, brackets, and planting tools. These iron casting parts help machines run well and last longer. Iron castings are also used in irrigation and other special farm systems.

Tip: Picking the right iron casting parts helps farm equipment work better and last longer.

Pros and Cons of Steel and Iron

Steel Advantages and Disadvantages

Steel is a top pick for farm machine parts. It is strong and reliable. Farmers and makers like steel for tough jobs. Steel casting lets people make many shapes. Makers can create big or special parts. They can change steel’s properties by using different alloys. Heat treatment makes steel even better. Investment casting with steel saves time and cuts waste. This method gives smooth parts right from the mold. Strict checks help make sure steel parts are safe. Non-destructive tests check for hidden problems. Steel casting helps get parts to market fast.

But steel casting has some downsides. Making special molds costs a lot at first. Small or tricky parts can be expensive. Sometimes, parts need extra work to fit just right. This adds to the price. Steel parts can have holes or weak spots. Careful checks are needed to find these. Some foundries cannot make all types or sizes of steel parts. Steel casting uses lots of energy and makes waste. This can hurt the environment.

Tip: Use investment casting with steel for strong, precise, and long-lasting parts. But plan well and be ready to spend more.

Iron Advantages and Disadvantages

Iron is still used a lot for farm machine parts. It is strong and does not cost much. The table below shows the main good and bad points of iron:

| Pros of Iron Casting | Cons of Iron Casting |

|---|---|

| High durability and strength for tough conditions | Casting flaws require advanced quality control |

| Excellent wear resistance for longer equipment life | Machining can be complex and needs precision |

| Good corrosion resistance, ideal for irrigation systems | Weight may limit design and handling |

| Affordable materials and production | |

| Good machinability and castability for complex parts | |

| Damping properties reduce vibration and noise |

Iron casting, especially with investment casting, makes strong and tough parts. Iron has lots of carbon, so it is good for heavy machines. Iron is easy to shape and cut for detailed designs. Its damping helps stop shaking and noise. Iron also moves heat away, so machines do not get too hot.

But iron casting can have problems. Flaws can happen, so checks must be careful. Cutting iron parts needs special tools and skill. Iron is heavy, so it can make machines hard to move. Even with these issues, iron casting is still a good and cheap choice for many farm uses.

Choosing the Right Material

Factors to Consider

Picking the right material for agricultural machinery casting parts takes careful thinking. Every farm and machine is different. Farmers and engineers look at many things before they decide:

- Material Properties: Strength, wear resistance, corrosion resistance, and toughness are very important. Parts that touch dirt or work in rough fields need to last. Steel is strong and lasts a long time. Ductile iron is tough and can bend a little. Gray iron is easy to shape and helps stop shaking.

- Production Needs: How many parts you need and their shapes matter. If the part is tricky, investment casting is best. It makes accurate parts and uses less metal. Sand casting is good for big, simple parts.

- Environmental Conditions: Machines in wet or harsh places need stainless steel. Jobs with lots of pressure use cast iron or alloy steel. High heat needs special steels that can take the heat.

- Machinability: Some materials are easier to cut and shape. Cast iron is easier to machine than steel. This can save time and money.

- Cost: Cast iron usually costs less than steel or stainless steel. Farmers must think about price, how long the part will last, and how well it works.

- Heat Treatment: Heat treatment, like tempering or hardening, makes parts stronger and last longer. It is better to machine the part before heat treatment. This stops problems with cutting hard metal.

Tip: Always pick the material that fits the job. A part that gets a lot of wear or works in tough dirt needs a different material than a part that stays dry or carries light things.

The table below shows how these things affect the choice between steel and iron for agricultural machinery:

| Factor | Steel | Cast Iron |

|---|---|---|

| Strength | High, good for heavy loads | Good, best for compression |

| Wear Resistance | Excellent (with heat treatment) | Good, especially gray iron |

| Corrosion Resistance | Best in stainless steel | Moderate, needs coating |

| Machinability | Moderate | High |

| Cost | Higher | Lower |

| Suitability | Complex, high-stress parts | Stable, vibration-damping parts |

Practical Tips

Farmers and makers can use these tips to pick the best material for farm machines:

- Think About the Working Conditions

Machines in muddy, rocky, or wet fields need parts that fight wear and rust. Stainless steel or treated steel works well here. Cast iron is good for dry or easy jobs. - Choose the Right Casting Process

Investment casting makes accurate shapes and uses less metal. Sand casting is better for big, simple parts. Pick the process that fits the part’s size and shape. - Plan for Heat Treatment

Heat treatment makes parts harder and last longer. Cut and shape the part before heat treatment. This makes it easier to work with. - Test and Check Materials

Makers test model alloys to see how they work. They check for strength, wear, and rust resistance. This helps make sure the part will work well on the farm. - Work with Experts

Engineers and skilled foundries help pick the best material and casting method. They also make sure the parts are good quality and fit the machine. - Balance Cost and Performance

Cheaper materials may save money at first but might wear out fast. Better materials can help machines work more and break less. - Check Certifications and Quality

Good suppliers give certifications and outside testing. This makes sure the material is right for farm equipment and keeps machines safe.

Note: Picking the right material and casting process helps farm machines last longer, work better, and get more done on the farm.

Experts say you should pick materials for farm machine parts by thinking about the job, where the machine will be used, and how much money you have. Cast iron is cheaper, lasts a long time, and helps stop shaking. Steel is very strong and does not rust easily. Talking to skilled makers can help you choose the best material for your machine. Many farms work better when they use the right casting process and material. You can share your stories or ask questions in the comments.

FAQ

What is the main difference between steel and iron in farm machinery parts?

Steel is stronger and tougher than iron. Gray iron is better at stopping vibration. Iron is also easier to shape into parts. Farmers pick steel or iron based on what the part does and where it works.

Why do some parts use ductile iron instead of steel?

Ductile iron is strong and can bend a little. It can take hits without breaking. Makers use ductile iron for parts that get a lot of shaking, like tractor linkages.

Is stainless steel always better for wet environments?

Stainless steel does not rust or corrode easily. It is best for wet or chemical places. But it costs more than regular steel or iron.

How does material choice affect repair and maintenance?

Steel parts last longer and do not break as much. Iron parts can wear out faster but are cheaper to swap. Picking the right material helps machines work longer and saves money.

Can farmers mix steel and iron parts in the same machine?

Yes, many machines use both steel and iron. Steel is good for frames and axles. Iron works well for housings and gearboxes. Using both lets each part do its job best.