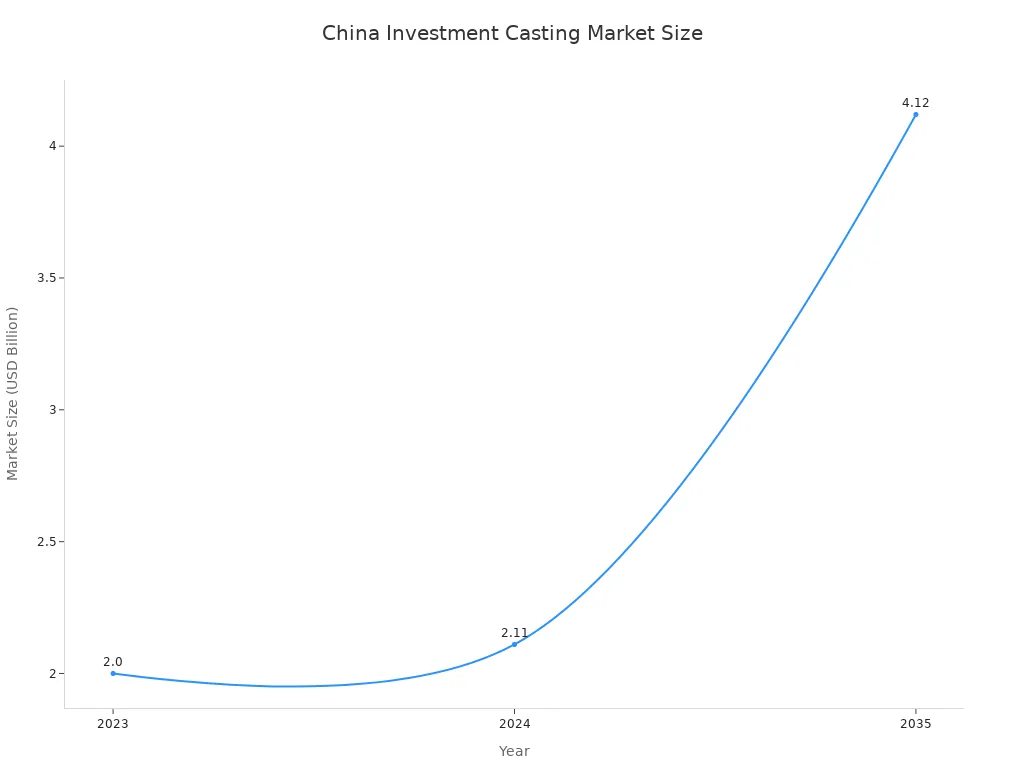

China’s investment casting industry is growing fast. It is expected to reach $2.11 billion in 2024. The industry will grow about 6.259% each year until 2035.

The top investment casting manufacturers in China for 2025 are KEMING, Besser Casting, CFS, Taiyuan SIMIS, ChinaSavvy, Dongying Vast Precision Casting, Dawang Metals, Vast-cast, Dongguan Cast Dream, and Ningbo Precision Casting. KEMING is known for using advanced technology and having a lot of experience.

Picking the right investment casting manufacturer is important. It helps make sure you get good quality, accuracy, and dependability in many industries. Experts say you should look at experience, certifications, how much they can produce, and customer support when choosing investment casting manufacturers and suppliers in China.

Top 10 China Investment Casting Manufacturers

Choosing the right investment casting manufacturer in China is very important. It can help make your products better and your projects successful. Here are the top 10 investment casting manufacturers for 2025. They are known for their skill, new technology, and good reputation.

KEMING (Ningbo, Zhejiang)

KEMING is a top china investment casting manufacturer with over 20 years of work. The company has a modern investment casting factory with advanced CNC machines. There are two casting process lines in the factory. KEMING makes more than 2,000 tons of castings every year. They serve many industries like automotive, aerospace, marine, medical, and machinery. Their precision casting can make over 5,000 products in 100 materials. These include stainless steel, aluminum, carbon steel, alloy steel, ductile iron, and bronze.

Certifications and Quality Standards:

- KEMING has ISO 9001:2008 certification for quality management.

- The company uses strict quality control that matches global standards like ASTM, DIN, and JIS.

- Every casting is tested to make sure it has no defects.

KEMING’s investment casting foundry uses the lost wax process. This helps them make complex parts with tight tolerances and smooth surfaces. Their OEM and ODM services let customers get custom products. This makes KEMING a popular choice among investment casting companies in China.

Besser Casting Co., Ltd. (Dongying, Shandong)

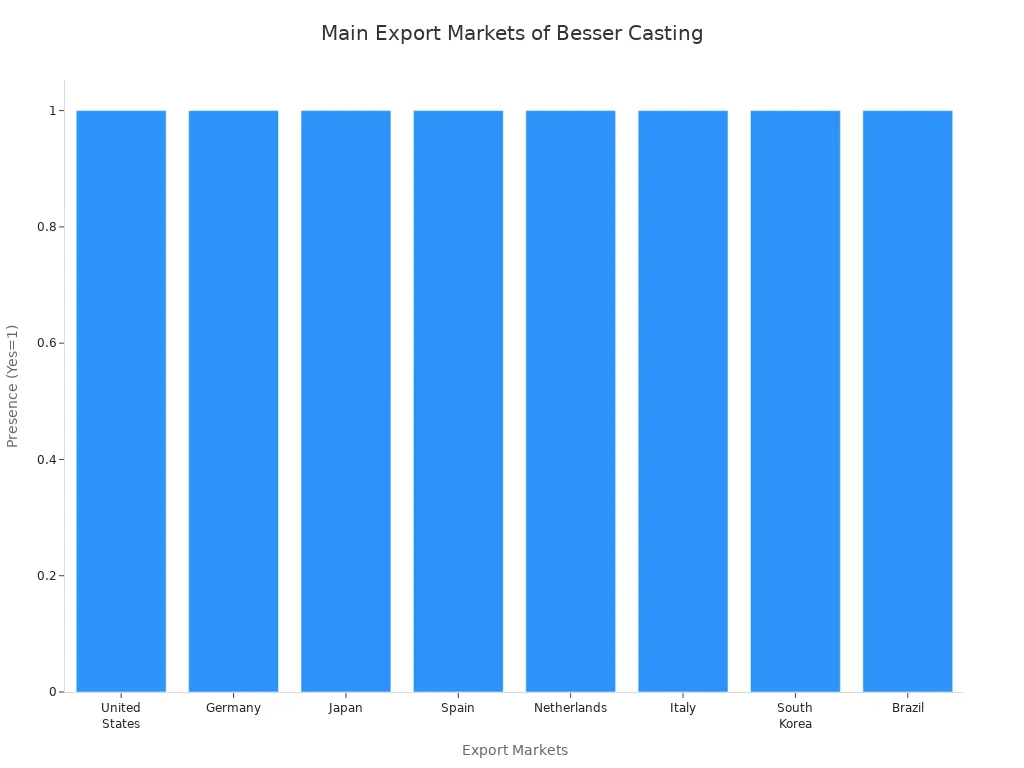

Besser Casting Co., Ltd. is a big investment casting manufacturer. Their investment casting foundry is 12,000 square meters in size. About 170 skilled workers work there. Besser Casting serves many industries like construction hardware, auto parts, valve parts, and tool parts. They export to the United States, Germany, Japan, Spain, Netherlands, Italy, South Korea, and Brazil.

| Aspect | Details |

|---|---|

| Factory Area | 12,000 square meters |

| Workforce | About 170 professional and technical personnel |

| Casting Weight Range | 0.005 kg to 50 kg |

| Certifications | IATF16949:2016, ISO9001:2015 |

| Casting Tolerances | ISO 2768-mK, VDG P690 D1-D2, ISO8062-3-2007 DCTG4-6, GCTG4-6 |

| Main Export Markets | USA, Germany, Japan, Spain, Netherlands, Italy, South Korea, Brazil |

| Industries Served | Construction hardware, auto parts, valve parts, tool parts, and others |

CFS Co., Ltd. (Ningbo, Zhejiang)

CFS Co., Ltd. is a well-known china investment casting manufacturer. They are famous in the logistics and supply chain sector. The company uses cloud-based and customizable software. CFS automates manual work and connects with customs, transport, finance, and freight systems. Their mobile tools give real-time updates. This helps clients work faster and see what is happening.

Taiyuan SIMIS Precision Casting Co., Ltd. (Taiyuan, Shanxi)

Taiyuan SIMIS Precision Casting Co., Ltd. has six casting facilities and two CNC workshops. The company offers many casting processes. These include investment casting, sand casting, die casting, and shell mold casting. Their products include bronze precision castings, catalytic converters, automotive parts, refractory materials, and ceramic foam filters. Taiyuan SIMIS serves industries like automotive, aerospace, chemical, construction, and energy. This shows they are large and flexible as an investment casting foundry.

ChinaSavvy (Guangzhou, Guangdong)

ChinaSavvy is an ISO 9001:2008 certified investment casting company in Guangzhou. The company makes near-net shapes with fine detail and strong mechanical properties. ChinaSavvy offers fast forming services for quick delivery. This helps clients get investment castings for testing. Their focus on quality and design freedom makes them a trusted partner for precision casting projects.

Dongying Vast Precision Casting (Dongying, Shandong)

Dongying Vast Precision Casting is a trusted investment casting manufacturer in China. The company makes many types of castings for automotive, machinery, and construction. Their investment casting foundry uses advanced methods. This helps them make strong, high-quality parts that meet world standards.

Dawang Metals (Cangzhou, Hebei)

Dawang Metals is known for quality and customer satisfaction in investment casting. The company has three casting factories that cover 120,000 square meters. They have certifications like ISO9001, ISO14001, OHSAS18001, IATF16949, PED, AD2000, and DNV/GL. Dawang Metals serves clients in Asia, North America, and Europe. They make high-quality steel castings for construction, energy, heavy machinery, and automotive. Their global support and new technology make them a top investment casting manufacturer.

Vast-cast (Ningbo, Zhejiang)

Vast-cast uses new technologies like 3D printing, laser jetting, and temperature control. This helps them make patterns and castings more accurately. Their investment casting foundry makes pump valves, glass spigots, architectural hardware, lost wax investment castings, and marine hardware. Vast-cast is skilled in precision casting. They make complex stainless steel parts for high-performance uses.

Dongguan Cast Dream (Dongguan, Guangdong)

Dongguan Cast Dream offers many services. These include urethane casting, vacuum casting, CNC prototyping, and surface finishing. The company supports small and medium batch production of plastic and metal parts. They serve industries like automotive, healthcare, consumer electronics, and industrial equipment. With over 100 materials and custom solutions, Dongguan Cast Dream gives fast delivery and custom products for prototypes and low-volume runs.

| Category | Details |

|---|---|

| Services Offered | Urethane casting, vacuum casting, CNC prototyping, surface treatment, small to medium batch production |

| Industries Served | Automotive, healthcare, consumer electronics, industrial equipment |

| Materials Available | Over 100 materials including metals and plastics |

| Customization Options | Prototype models, fast delivery, tailored solutions |

Ningbo Precision Casting Co., Ltd. (Ningbo, Zhejiang)

Ningbo Precision Casting Co., Ltd. is a large investment casting factory. It can design 95,000 tons of castings each year. The company exports 90% of its products. They sell to North America, Europe, and Asia. Their main products are rail transit parts, engineering machinery parts, truck parts, marine hardware, and pressure vessel valves. Ningbo Precision Casting has strong R&D and testing. This helps them make high-quality castings for tough jobs.

| Product Category | Description / Details |

|---|---|

| Rail Transit | Products for North America, Europe, and CRRC heavy-duty freight and high-speed trains |

| Engineering Machinery | Parts for excavators, loaders, mining machinery |

| Truck Parts | Steel castings for American freight trucks |

| Marine Parts | Marine rope buckles, high-stress components |

| Valves | Pressure vessel components with advanced casting technology |

| Annual Design Capacity | 95,000 tons |

| Export Percentage | 90% of products |

Note:

These top china investment casting manufacturers are the best in the industry. They use new technology, strict quality control, and offer many types of castings for the world market. Each investment casting foundry has special strengths. This makes them good partners for precision casting needs.

Investment Casting Capabilities in China

Materials and Alloys

Top investment casting foundries in China use many materials. These include stainless steels, carbon steels, alloy steels, ductile iron, bronze, and aluminum alloys. Some manufacturers also use special metals like superalloys and beryllium copper for tough jobs. Chinese investment casting foundries follow global rules like ASTM, DIN, and JIS. This helps them make good products for aerospace, automotive, marine, and medical industries.

- Aluminum bronze and nickel-aluminum bronze do not rust in seawater, so they are good for marine castings.

- Brass and leaded bronze are easy to machine and do not rust, so they work well for plumbing.

- Copper alloys are used in electronics because they carry electricity well.

- Strong copper alloys, like beryllium copper, are used in aerospace and defense.

| Material Category | Common Alloys / Grades | Key Characteristics / Features | Typical Applications |

|---|---|---|---|

| Stainless Steels | CF3 (304L), CF8 (304), CF3M (316L), CF8M (316) | Corrosion resistance, weldability, pitting resistance | Food equipment, valves, pumps, marine parts |

| Carbon & Alloy Steels | 1020, 1045, 4140, 8620 | Good machinability, strength, fatigue resistance, heat treatable | Structural parts, gears, shafts, bearings |

| Cast Irons | Gray Iron (ASTM A48), Ductile Iron (ASTM A536) | High machinability, toughness, wear resistance | Engine blocks, valve bodies, pump housings |

| Tool Steels | D2, H13, A2 | High wear resistance, heat resistance, dimensional stability | Dies, molds, stamping tools |

| Copper Alloys | Aluminum bronze, nickel-aluminum bronze | Corrosion resistance, seawater resistance, machinability | Marine components, pump parts, electrical |

| Superalloys | Inconel, Monel, Hastelloy, Beryllium copper | High strength at elevated temperatures, corrosion resistance | Aerospace, chemical, marine industries |

KEMING can make over 5,000 types of castings in more than 100 materials. This wide choice helps them make complex and high-quality castings.

Production Technology

Chinese investment casting manufacturers use new technology for precision casting. Most investment casting foundries have machines that inject wax, fast drying rooms, and robots to build shells. Induction furnaces melt metals quickly. CAD modeling and CNC machining help make accurate tools and parts. The silica sol investment casting process makes shells stronger and dries them faster, so production is quicker.

- Machines like spectrometers and X-ray systems check product quality.

- Smart manufacturing helps factories work better and track products.

- Heat treatments and surface finishes, like painting or galvanizing, make metal parts last longer.

KEMING’s investment casting foundry has two casting lines and modern CNC machines. They can make more than 2,000 tons of castings each year for customers around the world.

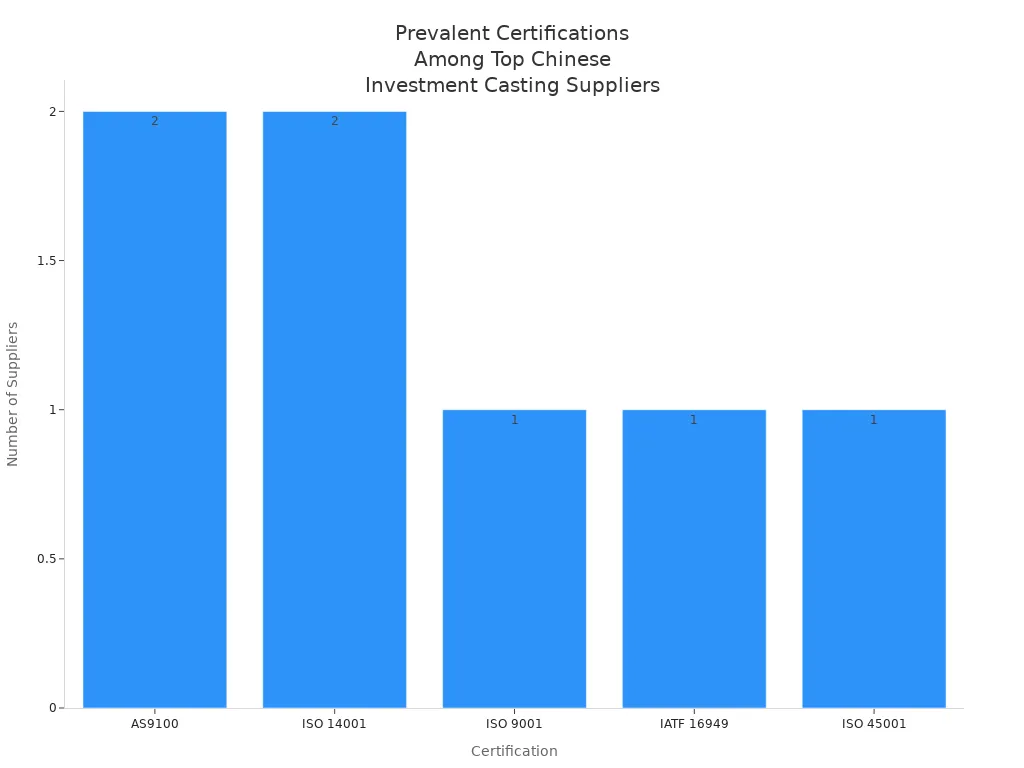

Quality Standards

Top investment casting suppliers in China have strict quality checks. They have certifications like ISO 9001, IATF 16949, ISO 14001, AS9100, and ISO 45001. These show they care about quality, safety, and the environment. Each investment casting foundry checks castings at every step to make sure products are good and have few defects.

KEMING’s investment casting process follows world standards. Their team checks every casting for accuracy and smoothness. This focus on quality helps them give customers the high-quality castings they need.

Choosing Investment Casting Manufacturers

Picking a good supplier for castings in China is important. You need to look at a few main things. These things help you get good quality, save money, and have an easy process.

Certifications and Experience

Certifications mean a company follows strict rules for quality. You should find suppliers with ISO 9001 or IATF 16949 certifications. These show the castings meet world standards. Experience is also very important. Companies that have worked for many years do better work. They know how to fix problems and handle hard jobs. KEMING, for example, has over 20 years of experience and ISO 9001:2008 certification. This helps them keep their products high quality and dependable.

Tip: Always ask to see the certifications. Also, check how long the supplier has been making investment castings.

Customization and OEM/ODM

Custom castings let buyers get parts that fit just right. Top suppliers in China offer both OEM and ODM services. These services help customers make special castings from drawings or samples. Custom solutions are needed in industries like automotive, aerospace, and medical. In these fields, every detail is important. KEMING makes custom castings in over 100 materials. They can handle both small and big orders.

- Custom castings can have special shapes or thin walls.

- OEM and ODM services help turn ideas into real products fast.

- Talking clearly with the supplier helps make sure the castings are right.

Production Capacity

Production capacity means how many castings a factory can make and how fast. China has many casting factories, from small shops to big plants. Some, like those in Dandong, can make up to 17,000 tons each year. Others, like SAIVS, can make about 2,000 tons a year. This means they can handle big orders for cars, machines, and buildings.

| Factory Location | Annual Capacity (tons) |

|---|---|

| Dandong Factory 1 | 8,000 |

| Dandong Factory 2 | 9,000 |

| Total (post-renovation) | 17,000 |

Note: Make sure the factory can handle your order size. Big projects need factories that can make a lot. Small projects may do better with flexible suppliers.

To pick the best investment casting partner, check their certifications, experience, custom options, and how much they can make. This helps you get good castings that fit your needs.

How to Work with China Investment Casting Suppliers

Inquiry and Quotation

When you start working with Chinese investment casting suppliers, you need to ask for a quote. You should make a Request for Quotation, or RFQ. This RFQ must have all the details about your part. It should say what material you want, show drawings, list tolerances, and explain how smooth the surface should be. You also need to say how you will check the parts. The steps are simple:

- Send your RFQ and ask for a price.

- Talk about the details and ways to save money.

- Look at quotes from different suppliers.

- Make sure the supplier is real and can do the job.

- Talk about payment, delivery time, and other rules.

- Agree on everything before making any tools.

Tip: Always check if the supplier has the right certifications. Look at their past work. You can visit the factory or hire someone to check it for you. This helps you get good investment casting services.

Sample and Prototyping

After you agree on the main points, the supplier makes tools and sample castings. Most top investment casting manufacturers in China send samples in 10 to 15 days. If you use rapid prototyping, like 3D printing, you can get simple samples in 30 minutes. The table below shows how long it takes:

| Service Type | Lead Time Range |

|---|---|

| Sample Castings | 2 to 4 weeks |

| Rapid Prototyping (3D Printing) | 30 minutes to 7 days |

You should check the samples before making lots of parts. If you want changes, tell the supplier right away. This helps stop problems later.

Contract and Production

If the samples are good, you and the supplier sign a contract. The contract should say when you get your parts, how you pay, and who owns the molds. Then, the supplier starts making your parts. Sometimes, they make a small batch first. This helps make sure everything is right. Talking often with the supplier helps you get the parts you want.

Inspection and Delivery

Checking quality is very important in investment casting. Good suppliers use special machines to check the parts. They look at the material, size, and inside of each part. At the end, they check again to make sure the parts meet world standards. After passing all checks, the supplier ships the parts to you. Many factories are close to big ports, so shipping is fast and costs less. Good planning and on-time delivery help you get your castings quickly.

Note: Stay in touch with your supplier during every step. This helps you get updates and support. It also makes sure your parts are made well and delivered on time.

Top Chinese investment casting manufacturers make great products. They use new technology and have strong research teams. They also check quality very carefully. The table below shows what makes each one special:

| Manufacturer | Key Strengths |

|---|---|

| KEMING | Precision, reliability, broad material range |

| Guangzhou Foundry Works | Advanced simulation, tailored solutions |

| Dongying Precision Casting | Complex designs, rigorous quality control |

| Suzhou Industrial Casting | Innovation, rapid prototyping |

| Qingdao Metal Casting | Modern tech, eco-friendly practices |

Buyers should make sure the supplier is real. It is smart to visit the factory if you can. Always talk clearly with the supplier. You can ask these companies for prices. Start by making drawings and listing what you need for your parts.

FAQ

What industries use investment casting from China?

Factories in China make investment castings for many industries. These include automotive, aerospace, marine, medical, and machinery. These fields need metal parts that are strong and detailed. Chinese suppliers follow strict rules for quality in each industry.

How does KEMING ensure casting quality?

KEMING uses advanced CNC machines to make castings. Their team checks every part at each step. They use world standards like ASTM, DIN, and JIS. This helps them make castings that are strong and have no defects.

Can suppliers handle custom designs or small orders?

Yes, most top suppliers offer OEM and ODM services. They can use custom drawings or samples from clients. Many factories make both small and big orders. This helps customers who need special or low-volume parts.

What is the typical lead time for investment castings?

Lead time depends on how big and hard the project is. Most suppliers send samples in 2 to 4 weeks. Full orders may take 4 to 8 weeks to finish. Rapid prototyping can give samples in just a few days.

How do buyers communicate with Chinese investment casting suppliers?

Buyers talk to suppliers by email or online platforms. Clear drawings and material needs help avoid mistakes. Many suppliers have staff who speak English for easy communication.