You can find many kinds of wax used in investment casting. These include filled pattern wax, non-filled pattern wax, runner wax, sticky wax, water-soluble wax, paraffin, beeswax, jeweler’s wax, microcrystalline, vegetable, mineral, and special blends. Each wax type has unique features that affect how you create precise patterns for investment casting. Your selection depends on the level of detail, pattern size, and surface finish required for your investment casting project. If you want high-quality wax products, you can choose KEMING as your investment casting manufacturer.

Key Takeaways

- Choose wax based on your project’s size, detail, and finish needs to get the best casting results.

- Filled pattern wax works well for large, strong, and detailed patterns because it shrinks less and stays stable.

- Non-filled wax is easy to use, melts quickly, and recycles well, making it good for small or simple shapes.

- Special waxes like water-soluble, beeswax, and jeweler’s wax help create hollow shapes or fine details.

- Testing wax on a small scale before a big project saves time and ensures you pick the right type.

Pattern Wax Types

Filled Pattern Wax

Filled pattern wax has special things called fillers inside. These fillers make the wax patterns strong and steady. People use filled wax when they need patterns to be very exact. It also helps stop the patterns from shrinking too much. Fillers can be things like bisphenol-A, some organic stuff, or even water.

Here is a table that lists some key things about filled pattern wax:

| Property / Metric | Description / Effect |

|---|---|

| Thermal Expansion | Low thermal expansion keeps the pattern size steady. |

| Shrinkage | Very little shrinkage, so you do not need extra wax chills. |

| Dimensional Stability | High stability means you get accurate casting results. |

| Strength | Fillers make the wax pattern tougher. |

| Fillers Used | Fillers can be BPA, organic fillers, terephthalic acid, cross-linked polystyrene, or water. |

| Solidification Behavior | It hardens well and does not need extra cooling. |

| Surface Finish | Usually gives a smooth surface on the finished casting. |

| Recyclability Challenges | Harder to recycle because of the fillers inside. |

| Residue After Dewaxing | Might leave some residue, so you need more time to burn it out. |

| Flow Properties | How it flows can change with different fillers. |

Tip: If you want to make big or detailed patterns, filled pattern wax works well. It helps you keep the pattern’s size and shape right. This gives you better results in investment casting.

Non-Filled Pattern Wax

Non-filled pattern wax does not have any extra fillers. You use this wax when you want it to be easy to handle. It is also simple to recycle. Non-filled wax is softer and flows into molds easily. It is good for filling small or tricky molds. It works best for patterns that do not need to be super strong or exact in size.

- Advantages:

- Easy to melt and put into molds.

- Simple to recycle and use again.

- Leaves only a little residue after burning out.

- Limitations:

- Shrinks more than filled wax.

- Not as steady for big or detailed patterns.

You can pick non-filled pattern wax for small, simple shapes. It is also good if you want to save money. Always choose the wax that fits your project best. If you need help, KEMING can help you as a trusted investment casting manufacturer.

Runner, Sticky, and Water-Soluble Wax

Runner Wax

Runner wax helps you build the channels that guide molten metal into your mold. You use runner wax to create the “runners” and “gates” in the investment casting process. This wax needs to be strong and easy to shape. Runner wax usually has a higher melting point than pattern wax. This property keeps the runners stable during assembly.

Key properties of runner wax:

- Good strength for handling and assembly

- Higher melting point for stability

- Easy to cut and join

Tip: Runner wax works best when you need to make strong support structures for your casting. You can trust KEMING to supply high-quality runner wax for your projects.

Sticky Wax

Sticky wax acts like glue for your wax patterns. You use sticky wax to attach different wax parts together. It melts quickly and cools fast, so you can work quickly. Sticky wax holds parts in place during assembly, but it does not add much strength.

Advantages:

- Quick melting and setting

- Easy to use for joining small parts

Limitations:

- Not strong enough for large joints

- Can leave residue if overheated

You should use sticky wax for small connections or repairs. It helps you save time during the investment casting process.

Water-Soluble Wax

Water-soluble wax lets you make hollow or complex shapes. You use this wax to create cores inside your pattern. After you build the pattern, you can dissolve the water-soluble wax with water. This step leaves a cavity or special feature in your mold.

| Property | Benefit |

|---|---|

| Dissolves in water | Easy removal after assembly |

| Smooth surface | Good for detailed features |

| Low residue | Clean burnout |

Note: Water-soluble wax helps you create patterns that are hard to make with regular wax. If you want to try advanced investment casting techniques, ask KEMING for advice on using water-soluble wax.

Traditional and Specialty Waxes

Paraffin Wax

You will often see paraffin wax in investment casting because it melts quickly and costs less than many other waxes. This wax works well when you need to make patterns fast or want to save money. Paraffin wax has a lower melting point, so you can melt and shape it without much heat. It is a good choice for simple molds or when you need to release patterns from the mold easily.

Paraffin wax feels more brittle than other waxes. It can crack if you bend it too much. You may notice that it does not hold up well under long periods of heat. If you want a wax that is easy to use and budget-friendly, paraffin wax is a strong option. Many factories choose it for large runs of simple parts.

Tip: Paraffin wax is best for quick jobs and simple shapes. If you need help picking the right wax, KEMING can guide you.

Beeswax and Jeweler’s Wax

Beeswax gives you a natural and flexible option. It melts at a higher temperature than paraffin wax, so it stays strong even when things get hot. Beeswax does not crack as easily and keeps its shape well. You will find beeswax useful if you want to make detailed or delicate patterns. It also works well for projects that need a safe, non-toxic material.

Jeweler’s wax is a special blend made for fine details. You can carve it easily and get sharp lines. This wax is perfect for small, complex pieces like jewelry or tiny machine parts.

| Wax Type | Best Use | Key Benefit |

|---|---|---|

| Beeswax | Detailed, flexible patterns | High strength, safe |

| Jeweler’s Wax | Fine, small, complex patterns | Easy carving, precision |

Microcrystalline, Vegetable, and Mineral Waxes

Microcrystalline wax gives you a soft and sticky texture. You can use it to fill gaps or smooth out surfaces. This wax holds up better than paraffin wax when you need to bend or shape your pattern. Vegetable and mineral waxes come from plants or the earth. These waxes are good if you want an eco-friendly choice. They work well for special projects that need a natural or biodegradable material.

You might pick these waxes if you want to avoid petroleum-based products or need a wax that can handle more stress without breaking.

Special Wax Blends

Special wax blends mix different types of wax to give you the best features of each. You can find blends that melt at just the right temperature, flow smoothly, or hold fine details. Some blends add fillers for extra strength. Others focus on easy removal or a smooth finish.

You should choose a special blend if your project has unique needs. For example, if you want a wax that is both strong and easy to carve, a blend can help. KEMING offers many wax blends for investment casting, so you can match the wax to your exact job.

Note: Picking the right wax helps you get better results in investment casting. Think about the shape, size, and detail you need. Ask KEMING for advice if you are not sure which wax to use.

Investment Casting Wax Selection

Factors to Consider

When you pick wax for investment casting, you must think about a few things. Every project is different, so you need to choose the right wax for your job. Here are some main points to help you pick:

- Pattern Complexity

If your pattern has lots of small details, you need wax that flows well. Non-filled pattern wax or jeweler’s wax can fill tiny spaces. Water-soluble wax is good for making hollow or hard shapes. - Pattern Size

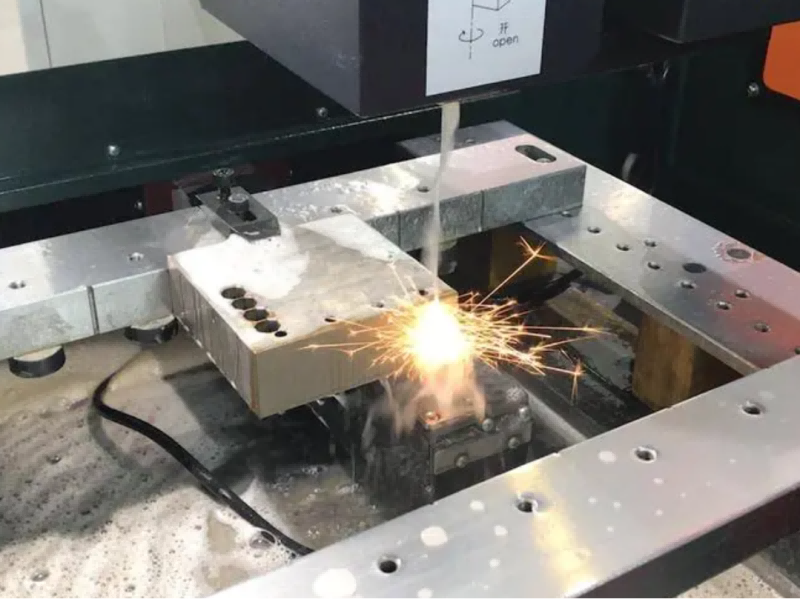

Big patterns need wax that keeps its shape. Filled pattern wax is strong and holds steady. For small or easy patterns, non-filled wax or paraffin wax saves money and time. - Surface Finish

The wax you use changes how your casting looks. Some waxes make the mold smoother. Using the right wax and electrode can give a shiny finish, almost like CNC molds. If you want a smooth look, pick microcrystalline or special blends. - Shrinkage and Stability

Some waxes shrink more than others. Dental waxes can change shape because they expand with heat. Filled pattern wax or special blends help stop shrinking and keep your pattern correct. - Cost and Recyclability

If you want to spend less, paraffin wax or non-filled wax is a smart pick. These waxes are easy to recycle and use again. For fancy or detailed work, you might need to pay more for special waxes.

Tip: Always try a small test before a big project. This helps you see if the wax works for you.

Application Guide

Use this easy guide to match your project with the right wax:

| Project Need | Recommended Wax Type | Why Choose It? |

|---|---|---|

| Fine details or small parts | Jeweler’s wax, non-filled wax | Easy to carve, fills tiny spaces |

| Large, strong patterns | Filled pattern wax | High strength, low shrinkage |

| Hollow or complex shapes | Water-soluble wax | Removes easily, forms cavities |

| Smooth surface finish | Microcrystalline, special blends | Good surface reproduction |

| Low cost, easy recycling | Paraffin, non-filled wax | Budget-friendly, simple to reuse |

| Eco-friendly projects | Vegetable, mineral wax | Natural, biodegradable |

Think about your casting steps too. Using positive pressure can help stop air bubbles and make the surface better. Many castings show that the right wax and method can really improve quality.

If you are not sure which wax to use, ask your supplier or an expert. KEMING has many wax types and can help you pick the best one for your project.

Note: Picking the right wax gives you better results, saves time, and cuts down on waste. Always match the wax to your project’s size, detail, and finish needs.

Choosing the right wax helps you get better results. Each wax type gives you different benefits for pattern strength, detail, and finish. You should look at your project needs before you decide. Ask your supplier or an expert for advice if you feel unsure. KEMING can help you pick the best wax for your investment casting work.

Tip: The right wax choice saves time and improves your final product.

FAQ

What is the best wax for investment casting?

You should choose wax based on your project needs. Filled pattern wax works well for large or detailed patterns. Non-filled wax fits simple shapes. For expert advice, you can contact KEMING, a trusted investment casting manufacturer.

Can you reuse wax after investment casting?

Yes, you can recycle some waxes, like non-filled or paraffin wax. Always check for contamination before reuse. Filled wax is harder to recycle because of the added fillers.

Why does wax shrink during investment casting?

Wax shrinks as it cools and hardens. Filled pattern wax shrinks less than non-filled wax. You can reduce shrinkage by choosing the right wax and controlling the cooling process.

How do you remove water-soluble wax from a pattern?

You can dissolve water-soluble wax with warm water. This step leaves a hollow space or special feature in your pattern. Always handle the pattern gently to avoid damage.